Explosion Proof Panelboards

Eaton Crouse-Hinds Series by Spike Electric

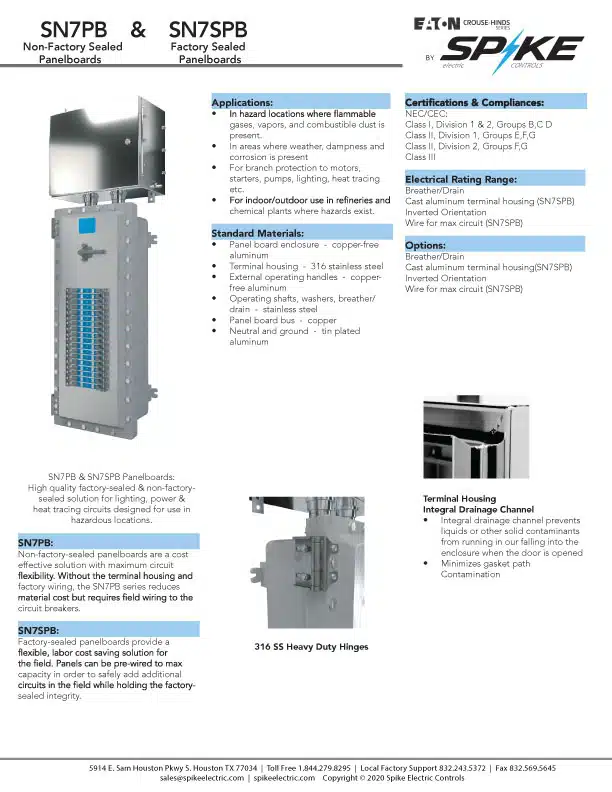

SN7PB & SN7SPB are two of many explosion proof panelboards that Spike Electric manufactures.

Eaton Crouse-Hinds Explosion Proof Panelboards

Explosion proof panelboards are the perfect solution in hazardous conditions. Specifically, they shine where the following are present:

- Flammable gases and/or vapors

- Combustible dust

Explosion proof panelboards are the perfect solution in hazardous conditions where flammable gases are present.

Explosion Proof Panelboard Solutions

The Only Certified Assembly Partner in the USA & Canada

At Spike Electric Controls, we're not just a Certified Assembly Partner for Eaton’s Crouse-Hinds series products — we are the only one in the USA & Canada. This distinction underscores our unparalleled expertise and commitment to delivering the best in explosion-protected product solutions. Discover our unique partnership with Eaton Crouse-Hinds as the only Certified Assembly Partner in the USA & Canada. For more details and verification, visit Eaton Crouse-Hinds Certified Assembly Partner.

Spike is strictly audited and certified by Eaton yearly to ensure they follow all quality and safety standards.

By choosing Spike Electric Controls, you're choosing a partner with a unique position in the industry—a partner verified and backed by Eaton Crouse-Hinds.

Our team's specialized training, certification, and local presence ensure you receive:

- Unmatched Service & Support

- Quick & Efficient Logistics: for immediate stock availability.

- Custom Assembly: of ATEX and IECEx-certified products to your exact specifications.

- Assurance of Adherence: to the highest quality standards set by Eaton Crouse-Hinds.

- Annual Audits: confirming our alignment with Hazardous Location Standards.

- Compliance: with the ISO 9001 Quality Management System, meeting Eaton's rigorous standards.

- Expertise: from in-house specialized hazardous location engineers.

- Exclusive In-house Hazardous Location Drilling & Tapping: guaranteeing certified, high-quality processes.

Why Choose A Spike Electric Product

Spike Electric provides the quickest delivery of the highest quality manufactured electric gear. We interact with our customers with high-quality customer service. That means you get:

- Two-Week Turnarounds (or faster) on Most Orders

- High Quality Manufacturing

- A Manufacturing Parter for Years to Come

- High Quality Customer Service

How does that translate into value for you? That’s simple.

Working with Spike Electric Controls means:

- Reduced Downtime

- Less Overtime for Your Staff

- Greater Operational Efficiencies

What is a Explosion-Proof Panelboard?

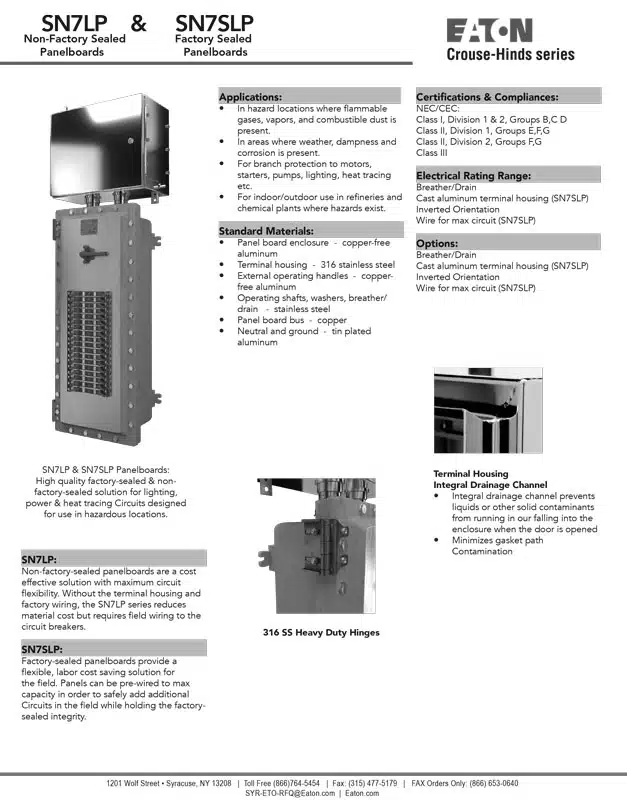

Explosion-Proof Panelboards are available in two main configurations: factory-sealed and non-factory-sealed. Factory-sealed panelboards are pre-wired to maximum circuit capacity, while non-factory-sealed panelboards require field wiring to circuit breakers and external seals to be field-installed during installation.

Explosion-Proof Panelboards are used in a variety of applications, including:

- Petroleum refineries

- Chemical and petrochemical plants

- Process industry facilities

- Other areas where there is a risk of explosion

The History of Explosion Proof Panel Boards:

The first Power Plus EPL and D2L Series Explosion-Proof Panelboards were created in the early 1990s.The history of explosion-proof panel boards is deeply intertwined with the industrial advancements and the increasing awareness of safety in hazardous environments. Here’s an overview:

Origin and Development:

- Early Industrial Age: During the 19th and early 20th centuries, as industries like oil and gas, mining, and chemical manufacturing grew, the need for safer electrical systems in potentially explosive environments became evident.

- Incidents Leading to Awareness: Numerous industrial accidents, often involving explosions triggered by electrical sparks or heat, highlighted the need for safer electrical equipment.

- Emergence of Safety Standards: In response to these safety concerns, various standards and regulations were developed. In the United States, the National Electric Code (NEC) started to include guidelines for electrical installations in hazardous locations by the early 20th century.

- Development of Explosion-Proof Technology: Manufacturers began to design electrical equipment that could contain any explosion within the device, preventing it from igniting the external atmosphere. This led to the development of explosion-proof panel boards.

Why They Were Created?

Containment of Explosions: The primary goal was to contain any ignition or explosion within the electrical panel, preventing it from triggering a larger, more catastrophic explosion in the surrounding environment.

Prevention of Ignition: These panel boards are designed to prevent electrical sparks or high temperatures that could ignite flammable gases, dust, or vapors.

Compliance with Safety Standards: To meet the stringent safety standards required in hazardous industrial environments.

Main Usages Today

- Oil and Gas Industry: Used in environments where flammable gases and vapors are present, such as offshore rigs, refineries, and processing plants.

- Chemical Manufacturing: For controlling electrical circuits in areas where explosive chemicals are processed or stored.

- Mining and Tunnelling: In underground mining operations where explosive dust and gases can accumulate.

- Pharmaceuticals and Grain Processing: In facilities where fine, combustible dust particles are a risk factor.

- Maritime and Offshore Applications: On ships and offshore platforms where the sea air can create a corrosive environment, adding another layer of complexity to electrical safety.

- Utilities and Power Generation: Especially in locations where the risk of explosive atmospheres is high.

Explosion-proof panel boards were developed in response to the need for safer electrical systems in hazardous industrial environments. Their primary function is to prevent electrical equipment from igniting explosive gases, dust, or vapors, and they are now a critical component in a range of industries where such hazardous conditions exist.

What is the Difference Between Factory-Sealed and Non-Factory-Sealed Explosion Proof Panel boards?

Factory-sealed and non-factory-sealed explosion proof panel boards are both designed to protect electrical circuits in hazardous locations. However, there are some key differences between the two types of panel boards.

Factory-Sealed Panel Boards

Factory-sealed panel boards are electrical panel boards that are pre-wired to their maximum circuit capacity and have all external seals in place, eliminating the need for field wiring or external sealing during installation. Factory-sealed panel boards are typically more compact and easier to install than non-factory-sealed panel boards. The stainless steel C1 D2 termination chamber, a compartment connected to the cast aluminum C1 D1 enclosure via seals.

The stainless-steel termination chamber houses hazardous location rated terminal blocks, ground bar, and neutral bar when needed, all terminations are pre-wired from the line side of the terminal blocks up to the load side of the breakers. The wires should be properly sized for the maximum breaker amps and passed through the seals between the stainless-steel termination chamber and cast aluminum hazardous location box.

All breakers, neutral, and ground are all pre-wired and tested to ensure that they meet the required safety standards. Depending on the manufacturer’s process the panel may or may not be sealed but should be sealed using Crouse Hinds Quick Seal by qualified personnel following the sealing instructions. After sealing the termination chamber is now rated for Class 1 Div 1 making the entire assembly the same rating. Should the cast aluminum hazardous enclosure have a UL Class 1 Div 1 rating, it is no longer valid and is derated to a Class 1 Div 2 panel.

It is important to have all wires neatly bundled and connected prior to sealing. If seals are not properly poured when gas enters the arcing and sparking chamber of the cast aluminum enclosure housing the circuit breakers, the flame will follow the path of least resistance and go into the C1 D2 stainless steel termination chamber, creating an explosion that will go into the stainless steel termination chamber and possibly have a catastrophic event by turning the stainless steel box into a bomb igniting the atmosphere.

Factory-sealed panel boards are easier to install as they require no field wiring or external sealing for the cast aluminum enclosure. They are also easy to maintain because all of the components are easily accessible. There is no need to unbolt 30+ bolts, thereby reducing the risk of field personnel failing to re-bolt the enclosure properly, which could allow rain and other elements inside.

Here are some of the benefits of using factory-sealed panel boards:

- Easy to install: Factory-sealed panel boards are pre-wired to maximum circuit capacity, eliminating the need for field wiring. This can save time and money on installation.

- Safe: Factory-sealed panel boards are designed to meet the highest safety standards. This includes the use of stainless steel C1 D2 termination chambers which helps in preventing the spread of fire or explosions.

- Easy to maintain: Factory-sealed panel boards are easy to maintain because all of the components are easily accessible. This can save time and money on maintenance costs.

Non-Factory-Sealed Panel Boards

Non-factory-sealed panel boards are simpler but require field wiring to circuit breakers, and external seals must be installed in the field during installation. This can be a more time-consuming process than installing a factory-sealed panel board. However, non-factory-sealed panel boards offer more flexibility, as they can be customized to meet the specific needs of the application. They are also more cost-effective than factory-sealed panel boards.

Which Type of Panel Board Should I Choose?

The ideal type of panel board for your application depends on your specific needs. If you require a panel board that is easy to install and does not necessitate field wiring or external sealing, then a factory-sealed panel board would be a good choice. If you require a panel board that can be customized to meet the specific demands of your application, a non-factory-sealed panel board would be a more suitable choice.

Here is a table summarizing the key differences between factory-sealed and non-factory-sealed explosion proof panel boards:

|

Feature |

Factory-Sealed Panel Boards |

Non-Factory-Sealed Panel Boards |

|

Pre-wired |

Yes |

No |

|

External seals |

In place |

Must be field-installed |

|

Installation |

Easier |

More time-consuming |

|

Maintenance |

Easier |

More time-consuming |

|

Flexibility |

Less |

More |

|

Hazardous Classification |

Class 1 Div 2 |

Class 1 Div 1 |

|

Voltage Max |

480V |

480V |

|

External Termination Chamber |

Yes |

No |

|

Cost |

Higher |

Less Expensive |

"We provide our customers with the quickest delivery possible of our high-quality services."

"Spike solutions result in reduced unplanned downtime, less overtime, and greater operational efficiencies."

The highest quality at the quickest speed.

Spike can deliver the same name-brand electrical gear in a fraction of the time.

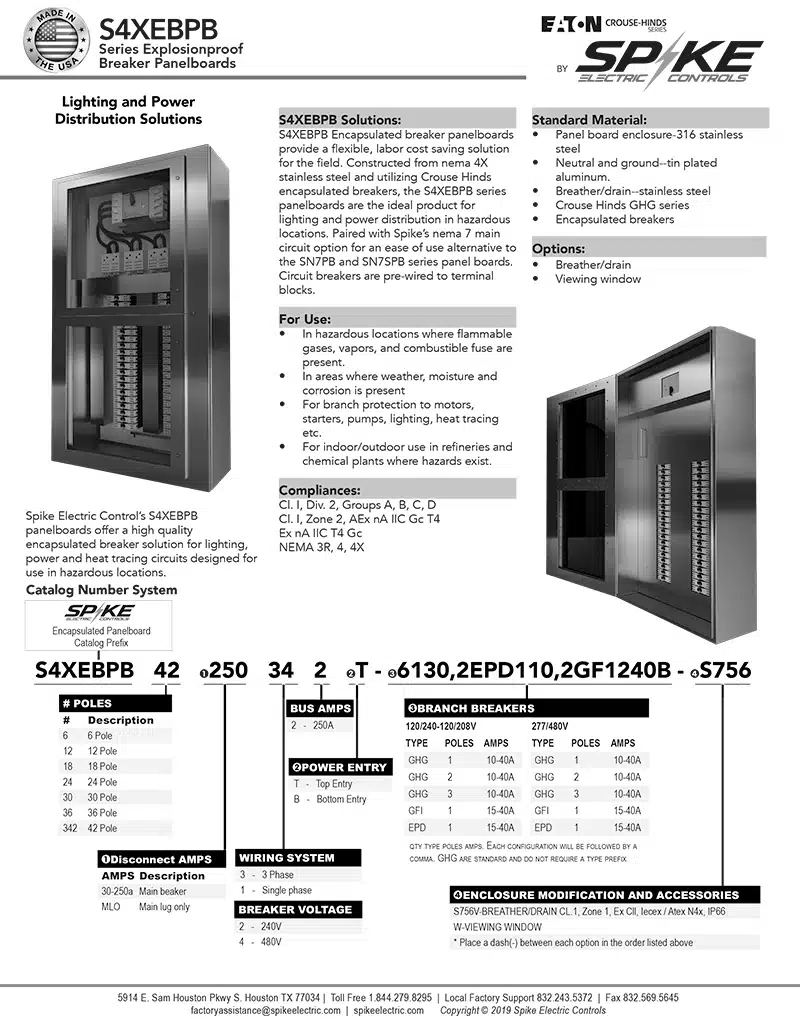

Certifications and compliances

(Not available for every model.)

- NEC/CEC:

- Class I,

- Division 1 & 2, Groups B, C, D

- Zone 1 & 2, IIB + H2

- Class II

- Division 1, Groups E, F, G

- Division 2, Groups F, G

- Class III

- NEMA/EEMAC:

- NEMA 3, 4, 4X

- NEMA 7BCD, 9EFG, 12

- CSA Enc. 3, 4, 5

- UL Standard: 67, 1203

- cUL (to CSA Standard C22.2 Nos. 29 & 30)

- IP65

Applications for Explosion Proof Panelboards

(Does not apply to every model.)

- In areas made hazardous by the continuous or abnormal presence of flammable gases, vapors, and combustible dusts

- Also in areas subject to weather, dampness, and corrosion

- For branch power distribution and circuit protection to motors, valves, pumps, lighting, heat tracing, receptacles, etc.

- Also for indoor and outdoor applications in petroleum refineries, chemical and petrochemical plants, and other process industry facilities where similar hazards exist

- To accommodate up to 100 amp branch loads (only 3 circuits), balance is up to 50 amps

How To Review Your Existing Suppliers

How does a late shipment affect you?

- First, does it result in production delays?

- Second, does it result in unbudgeted overtime?

- Finally, does it result in other expedite fees or expedited shipping costs?

What’s the true cost of quality to you?

- Does poor quality delay your production schedule?

- Does it consume other resources, such as engineering, that could be working on more productive tasks?

- How are future sales affected by a quality failure in the field?

Won’t it cost more to outsource than to do it internally?

- Do you have the proper equipment to machine the part internally?

- Do you have hazardous location UL listings?

- How is the quality with the internal process?

- Does the quality cause more problems in subsequent operations?

- If you consider lost labor time at all stages, what’s the true cost of the part?

- Can your existing labor be better utilized doing something else?

What other value-added services do you get?

- Are critical dimensions nominal, or just in tolerance?

- Do you get suggestions on cost savings?

- Before the parts are made, do you get print or tolerance errors pointed out?

- Do you get help during initial design stages, to reduce cost and time?