WHAT IS ELECTRICAL switchgear?

Explore Switchgear & the Value of A Custom Switchgear Manufacturer

Definition & Overview

All electrical systems & equipment require a power source (or sources) and distribute these sources to power downstream equipment, this is called power distribution. Electrical power distribution needs to be distributed in a safe and efficient manner. Electrical switchgear is an essential element of this distribution. Modern metal-clad switchgear has changed with new tech. But, many traits remain the same. The following is a summary of industry common applications and an attempt to explain what is included in the solutions. Switchgear is essentially a large metal box that houses items

like circuit breakers or fuses to protect the equipment it is distributing power to. Much like the circuit breaker box on the side of your house that send power safely into you home, the circuit break if it senses an issue it will trip before allowing electricity to continue to pass o that individual circuit. As a comparison the circuit breaker panel on the side of your house could be compared to a small car that can carry a few people, switchgear would be compared to a heavy duty large copper bus system that can carry dozens of people. Now lets dive a little deeper into Switchgear.

What are the main two types of Switchgear?

There is three main types or parents we will call them and they are defined by their

voltage.

- Low Voltage Switchgear – up to 1,000 volts

- Medium Voltage Switchgear over – 1,000 volts to 38kV

- High Voltage Switchgear – over 38kV to utility voltage 545kV

The (K) means Kilo or 1,000 volts in a for of measurement. The V means Volts. So

when describing 38kV we are saying 38,000 volts.

Components of Switchgear

As stated in the opening paragraph, Switchgear distributes power to smaller loads. The main power source could com various different sources. It has enough capacity to power the total need. A user of that power, often, is tasked with safely distributing this power once the service entrance from a utility is established. The most common way to make such a point is a metal enclosure, made in a factory. It includes at least the following:

- Metal enclosure called a switchgear enclosure

- Typical paint colors such as industry standard ANSI Gray paint. This also serves as a corrosion protectant.

- Bus Bars to carry the power source

- Non-metallic barriers and insulators to keep the bus bar away from the metal enclosure

- Main breaker, Main Fused Disconnect, or Main non-fused disconnect

- Protection devices such as breakers or fuses

- Protection Relays these are common on low voltage switchgear but medium and

high Voltage switchgear they are an requirement for each breaker. - Hardware there are specific types of fasteners and bolts used in switchgear

systems that are teste and approved by the manufacture. Its important to note

you cannot just use any standard hardware when making replacements - Control devices such as pilot lights for indication, switches or push buttons to

control the protection devices to do various operations such as Open / or Close/

Switchgear often includes components. They allow unsupervised and automated protection from failures in the electrical distribution system.

- Instrument transformers are electrical devices that sense power. They reduce voltage and current to safe levels. These levels are normally 120VAC and 5A. Relays and meters interpret these signals to show the state of the power.

- Circuit protectors are extra power sensors. They may or may not work with the instrument transformers. Their job is to stop the electrical system from damage to its insulation. This damage can be from short-circuits (phase to phase) or phase to ground. Examples are circuit breakers, current interrupting fuses, and load-break switches (manual and electrically operated).

- Protective relays interpret the power system operation. They often use the outputs of the instrument transformers. Based on those inputs, they send signals to alarm personnel or operate the circuit isolators. This isolates faults or overloads safely.

- Metering – allows for monitoring the power system operation. Control power transformer(s) allow for efficient power delivery. They provide power to the devices for operating the switchgear.

- Power transformers – unit substations, typically dry-type fan cooled. Using switchgear to hold many of these components has three benefits. It is efficient to make and install. It protects against outside factors that can harm electrical systems. And it guards people and property from the dangers of high voltage.

What do the terms and mean when referring to switchgear?

When you see a push button labeled “open” or “close” on the outside of switchgear or on the front of a breaker, it controls the contacts inside the breaker.

Pressing “open” disconnects the contacts, turning off or restricting the power flow through the breaker. Pressing “close” reconnects the contacts, allowing power to flow through the breaker to its downstream source. Think of this power flow like water running through a hose connected to a valve with push buttons: pressing “open” turns the valve, allowing water to flow, while pressing “close” shuts the valve, stopping the water flow.

As mentioned earlier, fuses can serve as protection devices, but they cannot be opened or closed like a breaker. If a fuse blows, it means the circuit is interrupted, and power will no longer flow through it. Fuses contain a strip of thin metal that melts or blows out when it reaches a certain temperature, stopping the power flow. To control a fuse in a piece of switchgear, a separate disconnect is needed in front of it. For low voltage, this would be a non-fused switch or knife switch to perform the open and close functions. For medium voltage, a load break switch or a larger equivalent is required, similar in function but scaled up.

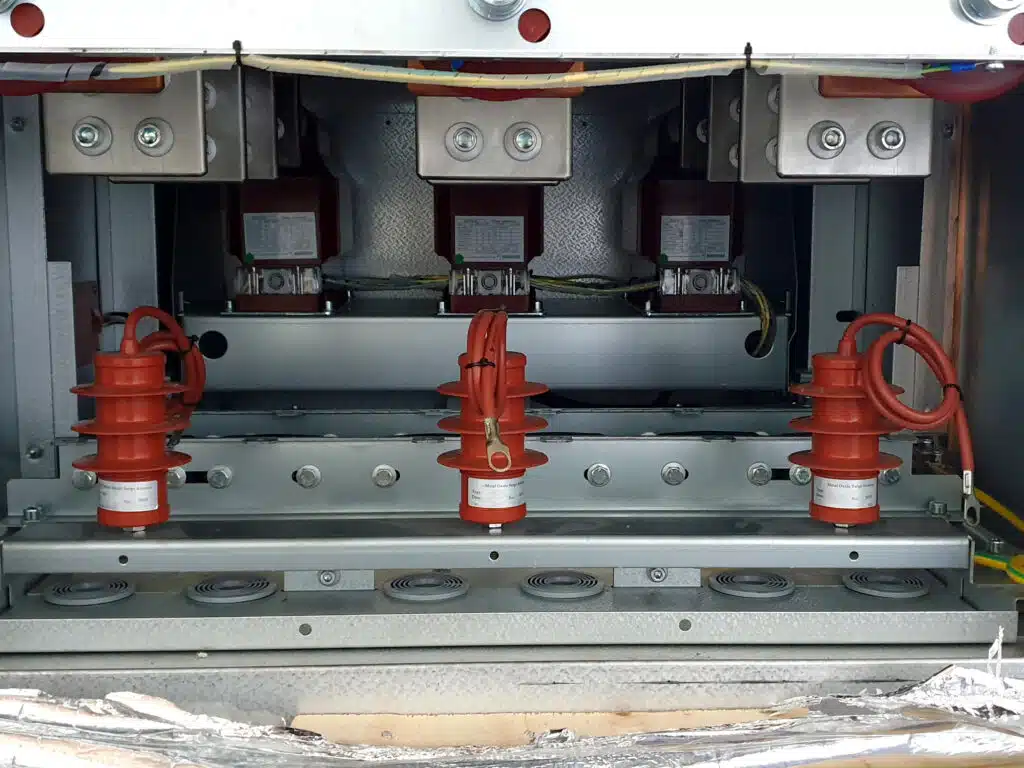

Here is an example of one of these switches and a set of fuses for medium voltage. Low voltage would be similar just smaller.

Enclosure Integrity and Composition

Switchgear enclosures are designed with varying levels of protection against external contaminants, suitable for both indoor and outdoor applications. They must accommodate power conductors, as well as external communication or control circuit connections. Modular designs allow users to route these systems efficiently while maintaining enclosure integrity, optimizing cooling, and maximizing space. Switchgear enclosures can be connected to transformer enclosures or motor control centers (MCCs), including large motor control cabinets for variable speed drives or soft starters, and panel boards.

Exterior surfaces can be made from powder-coated steel, stainless steel, or aluminum. The structural strength of the enclosure depends on the thickness of the material and the fastening methods used for its supports and sheathing. Enclosure integrity provides inherent protection, which can be further enhanced with an arc-resistant design. This classification ensures that any internal arc flash is contained, preventing harm to personnel and equipment.

Electrical Rating: Voltage

Switchgear enclosures are designed with varying levels of protection against external contaminants, suitable for both indoor and outdoor applications. They must accommodate power conductors, as well as external communication or control circuit connections. Modular designs allow users to route these systems efficiently while maintaining enclosure integrity, optimizing cooling, and maximizing space. Switchgear enclosures can be connected to transformer enclosures or motor control centers (MCCs), including large motor control cabinets for variable speed drives or soft starters, and panel boards.

Exterior surfaces can be made from powder-coated steel, stainless steel, or aluminum. The structural strength of the enclosure depends on the thickness of the material and the fastening methods used for its supports and sheathing. Enclosure integrity provides inherent protection, which can be further enhanced with an arc-resistant design. This classification ensures that any internal arc flash is contained, preventing harm to personnel and equipment.

Electrical Rating: Current

Switchgear enclosures are designed with varying levels of protection against external contaminants, suitable for both indoor and outdoor applications. They must accommodate power conductors, as well as external communication or control circuit connections. Modular designs allow users to route these systems efficiently while maintaining enclosure integrity, optimizing cooling, and maximizing space. Switchgear enclosures can be connected to transformer enclosures or motor control centers (MCCs), including large motor control cabinets for variable speed drives or soft starters, and panel boards.

Exterior surfaces can be made from powder-coated steel, stainless steel, or aluminum. The structural strength of the enclosure depends on the thickness of the material and the fastening methods used for its supports and sheathing. Enclosure integrity provides inherent protection, which can be further enhanced with an arc-resistant design. This classification ensures that any internal arc flash is contained, preventing harm to personnel and equipment.

Manufacturing Standardization

The standards for mechanical and electrical ratings of switchgear are developed by industry stakeholders, including manufacturers and users, to ensure safety and reliable performance. In North America, key standards and regulations include those from OSHA, NFPA, and ANSI/IEEE, particularly IEEE C37.20 series standards, which specify requirements for the design and application of switchgear. Globally, IEC standards apply to switchgear manufacturing. Some North American and international standards have been harmonized to ensure consistency.

OSHA qualifies Nationally Recognized Testing Laboratories (NRTLs) like UL, which certify that products comply with these standards. Federal, state, and local regulations then enforce the use of certified products in the field, ensuring that end-users are using approved, safe products.

Standardization in switchgear manufacturing aims to ensure that components are compatible and assemblies meet rigorous safety criteria, thus building user confidence. Properly applied, these standards help minimize risks to people and property by ensuring reliable performance. Switchgear is typically an enclosed system designed to distribute power safely, often connecting to transformers or motor control centers (MCCs) and may include various devices such as variable speed drives or power distribution products.

Designs strive to balance cost and complexity while providing essential functions, safely converting electrical energy into forms like mechanical or thermal energy. When implemented correctly, switchgear functions reliably, often unnoticed, as it protects people and equipment from electrical hazards.

Switchgear can be described as any free-standing enclosure that serves as an enclosed distribution system of electrical power. Designs are often a compromise. They minimize cost and complexity to provide an essential solution. This solution uses electrical energy. It safely converts it to another form, such as mechanical or thermal. When used correctly, switchgear is often a silent or invisible part of automated systems. They work as intended and silently protect people and property from harm.

Importance in Power Systems

Switchgear’s importance in electrical infrastructures cannot be overstated. It protects against hazards like power surges and overloads. These are critical in business and industry. Reliable and uninterrupted power is a necessity in today’s world, and Switchgear plays a central role in achieving this. Switchgear may operate silently behind the scenes. But, its role in keeping power systems running smoothly is clear. It is a crucial component, ensuring the safety and reliability of electrical networks.

A Shield Against Electrical Threats

- Switchgear has a robust design. It can withstand big power surges and unexpected overloads. It diverts the surge and isolates the affected area. This prevents widespread damage and potential outages.

- Safeguarding Critical Electrical Equipment: Switchgear protects costly electrical equipment. This equipment includes transformers, motors, and generators. It shields them from damage. The damage is due to power surges, short circuits, and other electrical faults. This protection extends the lifespan of these assets. It reduces the need for expensive repairs or replacements.

- Preventing Electrical Arc Faults: Switchgear’s arc-resistant design reduces the risk of arcs. These faults are potentially catastrophic. They can cause severe injuries, property damage, and widespread outages.

- Switchgear enhances personnel safety. Its protective features include grounding, compartmentalization, and interlocks. They safeguard people from electrical hazards. They prevent injuries and ensure a safe work environment.

The Cornerstone of Modern Power Infrastructure

- Switchgear is the backbone of modern power infrastructure. It enables efficient power distribution and control. Its presence allows for precise control of voltage and current. This ensures that power reaches its goal with minimal loss.

- Switchgear is crucial. It ensures reliable, uninterrupted power supply. This is a necessity for businesses, industries, and critical infrastructure. By preventing disruptions, Switchgear safeguards operations and minimizes downtime.

- Switchgear helps with maintenance. It allows for safe and efficient work on electrical systems. This reduces accidents and keeps the systems working well.

- Switchgear enhances system reliability. It isolates and protects faulty parts of the electrical system. This prevents widespread outages and keeps power flowing to critical areas. This uninterrupted operation minimizes downtime and maintains business continuity.

Historical Evolution of Switchgear

The evolution of Switchgear reflects the advancements in electrical technology. From the early days of simple designs to today’s sophisticated, digitally integrated systems, Switchgear has seen a remarkable transformation. This mirrors the rising demands and complexities of electrical distribution in many sectors. It shows the need for better and more reliable power management solutions.

Early History

- Late 19th Century: With the advent of commercial electrical power systems, devices to control and protect these systems became necessary. Early forms of Switchgear were simple knife switches. They were mounted on insulating panels of marble or asbestos.

- Early 20th Century: Oil-filled Switchgear appeared. They used oil to stop arcs. They were more reliable than older air-insulated switches.

Key Developments and Companies

- 1920s-1930s: The development of metal-enclosed Switchgear. Companies like Westinghouse and General Electric in the United States were instrumental in advancing the technology of Switchgear.

- 1950s: The introduction of vacuum and SF6 (sulfur hexafluoride) as arc extinguishing media marked significant advancements. SF6 is still widely used today. This is because it is effective and relatively safe for the environment. It is much safer than the oil-based systems used before.

- 1960s-1970s: The emergence of Gas Insulated Switchgear (GIS). European companies, including ABB and Siemens, played a significant role in developing GIS technology. GIS was advantageous in terms of space-saving and reliability, especially for high-voltage applications.

- 1980s-1990s: The advent of digital and microprocessor-based control systems revolutionized Switchgear. This era saw the integration of advanced protection, control, and monitoring technologies.

- 2000s-Present: The focus has shifted to sustainability, with developments in eco-friendly Switchgear using alternatives to SF6 gas, which is a potent greenhouse gas. Companies like Schneider Electric, ABB, and Eaton have been involved in these developments.

Modern Evolution

- Smart Switchgear integrates with smart grid tech. It offers advanced features, like remote monitoring and control.

- Modular and compact designs emphasize saving space. They are flexible for modern electrical infrastructure needs.

- Innovations are eco-friendly. They aim to find sustainable options to SF6 gas and other harmful parts.

Global Influence

Switchgear has developed and evolved globally. Companies and researchers in the United States, Europe, and Asia made big contributions. Each region has contributed to tech advancements and the adoption of global standards. This has shaped the Switchgear we know today.

Here is a break down of the timelines through history of the evolution of Switchgear:

Early History of Switchgear

| Event | Year |

| Benjamin Franklin experiments with electrical conductors and insulation materials | Late 18th century |

| Humphry Davy develops the first arc lamp | Early 19th century |

| Development of the first Switchgear devices, which were simple switches and fuses | Early 19th century |

Early 20th Century Advancements

| Event | Year |

| Hugh Cooper develops the first oil circuit breaker | 1903 |

| Development of more sophisticated Switchgear, including metal-clad Switchgear and air-blast circuit breakers | Early 20th century |

Late 20th Century and Beyond

| Event | Year |

| Switchgear technology continues to evolve. It is driven by the growing complexity of electrical systems. Also, by the demand for greater safety and reliability. | Late 20th century and beyond |

| Modern Switchgear uses advanced technologies. These include digital control systems, microprocessor-based relays, and fiber optic communication. | Late 20th century and beyond |

Timeline of Companies that Revolutionized Switchgear

|

Company |

Year |

Contribution |

|

Westinghouse Electric & Manufacturing Company |

1887 |

Develops the first commercial alternating current (AC) Switchgear. |

|

Hugh Cooper |

1903 |

Develops the first oil circuit breaker. |

|

General Electric (GE) |

1924 |

Introduces the first metal-clad Switchgear. |

|

Allis-Chalmers |

1939 |

Develops the first air-blast circuit breaker. |

|

Brown Boveri & Cie (BBC) |

1959 |

Develops the first vacuum circuit breaker. |

|

Siemens |

1969 |

Introduces the first gas-insulated Switchgear (GIS). |

|

Westinghouse Electric |

1970s |

Develops the first microprocessor-based relays. |

|

ABB (Asea Brown Boveri) |

1980s |

Introduces the first fiber optic communication systems for Switchgear. |

|

GE and Siemens |

2000s |

Develop advanced digital control systems for Switchgear. |

The Function of Switchgear

Imagine your building’s electrical system is like a busy city road network. Electricity travels like cars to different rooms and devices. Now, think of Switchgear as the traffic control system for this network. It’s like a powerful police officer. They can direct traffic, block roads during an accident, or open new routes. This “officer” ensures that electricity flows smoothly to where it’s needed, and more importantly, jumps into action to prevent accidents, like electrical overloads or short circuits.

In simpler terms, Switchgear is vital in electrical systems. It controls, protects, and regulates electricity. Here’s how it works and why it’s helpful:

- Traffic Director (Control): Switchgear directs the flow of electricity, turning it on or off as needed. Switchgear can switch power to different parts of a building or system. It’s like how traffic lights control the flow of cars.

- They can be things like electrical faults, sudden surges of electricity. Switchgear then acts like an emergency responder. It quickly cuts off the power in that “road” or circuit to prevent damage to the electrical network and keep everyone safe.

- Efficiency Monitor (Regulation): Switchgear also keeps an eye on how much electricity is flowing and where. It’s like a traffic manager. They ensure that no road (or circuit) is overloaded. They also ensure that everything runs smoothly and efficiently.

- Modern Switchgear can be very sophisticated. It can react to problems and anticipate and adjust to changing electrical demands. It is like a smart traffic system that adapts to changing road conditions.

In essence, Switchgear is the unsung hero in the background, ensuring that the electricity in our homes, offices, and factories is managed safely and efficiently. It’s like having a skilled traffic control team. They make sure that the complex electrical “roads” run without a hitch. They keep the lights on and machines running. They also protect us from electrical hazards.

Role in Managing Electrical Overload

Switchgear systems are specifically engineered to handle predetermined amounts of electricity. The current exceeds these limits. Then, the Switchgear acts as a safeguard. It protects the wiring and connected devices from overheating and damage. This protection is vital. It prevents system failures and hazards, such as fires. The system has special circuit breakers. They turn the flow of electricity on and off.

| Type of Breaker | Voltage Range | Switchgear Type | Description | Protection Functions | IEEE Rating |

| Molded Case Circuit Breaker (MCCB) | Up to 600V | Low-Voltage | A compact circuit breaker commonly used in low-voltage applications. | Magnetic trip (LSI) for short circuits, thermal trip (LS) for overloads, ground fault protection (GFI), arc fault protection (AFCI). | C37.20.1 |

| Solid-State Circuit Breaker (SSCB) | Up to 600V | Low-Voltage | A technologically advanced circuit breaker utilizing electronics for sophisticated protection. | Microprocessor-based protection, communication capabilities, adjustable protection settings. | C37.20.1 |

| Vacuum Circuit Breaker (VCB) | 4160V to 34.5kV | Medium-Voltage | A high-voltage circuit breaker known for its compact size and excellent insulating properties. | Overcurrent relays, overvoltage relays, differential relays. | C37.20.2 |

| Gas-Insulated Switchgear (GIS) | 4160V to 34.5kV | Medium-Voltage | A high-voltage circuit breaker system utilizing SF6 gas as an insulating medium. | Digital protection relays, integrated protection schemes, fiber optic communication. | C37.20.2 |

Note: Molded Case Breakers can be in the Switchgear Controls system. But, SSCB breakers will be used as the feeders.

Protective Mechanism Against Voltage Surges

Molded Case Breakers can be in the Switchgear Controls system. But, SSCB breakers will be used as the feeders.

| Protective Mechanism | Description |

| Surge Arresters | Divert high-voltage surges to ground, protecting sensitive equipment from damage. |

| Fuses | It melts under too much current. This interrupts the power flow and protects downstream equipment from damage. |

| Circuit Breakers | It can detect more types of faults. These include overcurrents, short circuits, and ground faults. It can be reset after tripping. |

| Metal-Oxide Varistors (MOVs) | It has non-linear resistance. It lets current flow freely under normal conditions. But, it diverts surge current to ground when there is a surge. |

| Spark Gaps | Conduct surge current to ground when a surge occurs. This ionizes the air between two electrodes. |

| Transient Voltage Suppression (TVS) Diodes | Conduct current in both directions, allowing them to divert both positive and negative surges to ground. |

| Overvoltage Relays | Monitor the voltage level and trip the circuit breaker if it exceeds a predetermined threshold. |

| Directional Relays | Protect against ground faults and other fault conditions in specific directions within the electrical system. |

| Distance Relays | Measure the impedance between the relay and the fault location to determine the distance to the fault and trip the nearest circuit breaker. |

| Differential Relays | Compare the current entering and exiting a transformer or other equipment. This is to detect internal faults and trip the circuit breaker. |

| Ground Fault Relays | Monitor the current flowing in the neutral conductor and trip the circuit breaker if the neutral current exceeds a predetermined threshold. |

| Arc Fault Detection and Protection (AFDP) Systems | Monitor the electrical waveform for patterns that are indicative of arcing faults and trip the circuit breaker. |

| Integrated Protection Systems | Incorporate multiple protection relays that work together to provide comprehensive protection. |

Components of Switchgear

Switchgear is vital. It controls, protects, and isolates electrical circuits. It houses various devices that work together to ensure the safe and reliable distribution of electricity. Here’s a detailed breakdown of the key components of Switchgear:

- Switches

Switches are the key parts of Switchgear. They make and break electrical connections. They are devices that physically move to start or stop current flow in a circuit. Switches come in various forms, including:

- Isolator switches:These switches provide complete isolation of a circuit, ensuring that no current can flow through it during maintenance or repairs.

- Disconnecting switches:Similar to isolator switches, disconnecting switches isolate a circuit but are designed for infrequent operation.

- Load break switches:These switches are capable of breaking current while under load, making them suitable for switching energized circuits.

- Fuses

Fuses are safety devices. They protect circuits from overcurrent, when too much current flows. This can cause damage or fire. Fuses have a thin strand of conductive material, like zinc or copper. This strand melts when it gets too much current. This stops the circuit and prevents more damage.

- Isolators

Isolators are special switches. They are made to ensure that a circuit is fully off before maintenance or servicing can be done. They provide a visible disconnect point. This lets technicians verify that the circuit is dead before working on it. Isolators are rated for full load current. They can break the circuit under faults.

- Relays

Isolators are special switches. They are made to ensure that a circuit is fully off before maintenance or servicing can be done. They provide a visible disconnect point. This lets technicians verify that the circuit is dead before working on it. Isolators are rated for full load current. They can break the circuit under faults.

- Circuit Breakers

Circuit breakers are switches. They operate automatically. They are designed to protect circuits from damage by excess current. They function similarly to fuses but offer more sophisticated protection and can be reset after tripping. Circuit breakers detect many fault types. These include overcurrent, short circuits, and ground faults. They interrupt the circuit to prevent damage.

- Lightning Arresters

Lightning arresters protect electrical systems from lightning damage. They are also known as surge arresters. They provide a low-resistance path for high-voltage surges. These surges are caused by lightning strikes. They let the surges safely flow to ground, protecting sensitive equipment. Lightning arresters are usually installed at the entry points of electrical systems. These points include power lines and transformers.

- Busbars

Busbars are the backbone of Switchgear. They conduct electricity. They are typically made of copper or aluminum and are designed to withstand high currents and temperatures. Busbars are arranged in many ways. This is to meet the specific requirements of the switchgear.

- Specialty Designed Metal Enclosure

Switchgear enclosures are made to endure the tough electrical environment. They protect the internal parts from things like dust, moisture, and impacts. The enclosure is usually made of metal, such as aluminum or stainless steel. It may have features like ventilation, grounding, and fireproofing.

- Arc-Resistant Switchgear

Arc-resistant Switchgear is designed to lessen the effects of electrical arcs. Arcs are high-energy discharges. They can cause severe damage to equipment and pose a safety hazard. Arc-resistant Switchgear incorporates various features to contain and extinguish arcs, such as:

- Arc chutes:These are specially designed channels that guide the arc away from sensitive components and towards grounding points.

- Pellicles are thin, insulating barriers. They help break up the arc and stop it from spreading.

- Arc flash mitigation systems use sensors, detectors, and suppressors. They detect and stop arc flashes. This reduces the risk of injury and property damage.

- Instrument transformers

These transformers convert high-voltage and high-current signals. They lower the levels for monitoring and control.

11. Control panels house the control circuitry and instruments. They allow for the operation and monitoring of the Switchgear.

12. Communication systems allow instant data exchange. They connect the Switchgear to other parts of the power grid. They allow remote monitoring and control.

13. Protection relays are essential in switchgear systems. They monitor electrical parameters like current and voltage. They ensure safe operation. They detect faults, such as overcurrents or short circuits, by seeing deviations from normal. It detects a fault. The relay decides whether to trigger a circuit breaker. It does this based on predefined settings. A protection relay’s main job is to send a trip signal to a breaker. This isolates the faulty section to prevent damage. Relays come in different types. These include overcurrent, differential, and earth fault relays. Each type is for specific protection needs. These relays are coordinated within the system to minimize disruption by only isolating the affected area. Modern digital relays have advanced features. They include things like communication and self-diagnostics. These features make electrical power systems safer and more efficient.

Protection Relays in Switchgear Systems:

Protection relays in a switchgear system are crucial. They ensure the safety and reliability of electrical power systems. Here’s a basic overview of how they work

Monitoring Electrical Parameters

- The relays protect. They watch various electrical things. These are current, voltage, frequency, and phase.

- They detect abnormal or fault conditions. These include overcurrent, undercurrent, overvoltage, undervoltage, frequency deviations, and phase imbalances.

Detection of Faults

- When a fault occurs, such as a short circuit or an overload, the electrical parameters deviate. They move away from their normal operating ranges.

- The relay detects these deviations. For example, an overcurrent relay will activate. It if the current goes over a set level.

Decision Making

- Once a fault is found, the relay decides whether to trip. It does this based on its settings and the fault’s nature.

- Relays can be programmed with ‘set points’ or ‘tripping characteristics.’ These settings determine their response to different conditions.

Initiating Action

- The relay decides that the fault is harmful. It sends a trip signal to a circuit breaker.

- This trip signal tells the circuit breaker to open. It isolates the faulty section of the network.

Types of Protection Relays

- The relay decides that the fault is harmful. It sends a trip signal to a circuit breaker.

- This trip signal tells the circuit breaker to open. It isolates the faulty section of the network.

Coordination

- Protection relays are coordinated in a system. They ensure that only the nearest breaker opens when there’s a fault. This minimizes disruption to the electrical network.

- This coordination is achieved by setting time delays and sensitivity levels appropriately.

Advanced Features

- Modern relays are digital. They have advanced features like communication, self-diagnostics, and data logging.

- They can be integrated into wider control systems for efficient monitoring and management.

Application in Switchgear

- In switchgear, these relays are key components. They ensure the system runs safely and well.

- They protect equipment. This equipment includes transformers, generators, motors, and transmission lines. They protect it from damage due to electrical faults.

- The reliability of these relays is critical for the overall safety of the electrical power system.

Protection relays are vital. They detect faults and stop damage to electrical equipment. They keep the power system stable and reliable.

Function and Importance of Each Component

Each component in a Switchgear system plays a critical role. For example, circuit breakers and fuses are protective devices. They guard against overcurrent and prevent potential hazards. Isolators and relays make it safe to operate and control electrical circuits. Lightning arresters protect the system from external disturbances.

Classification of Switchgear by Voltage

High-Voltage Switchgear (Above 38kV)

They are for managing high power. They are used in substations and power transmission. They have better safety measures. This is because of the high risks of handling such high voltages.

Medium-Voltage Switchgear (1KV to 38kV)

It is commonly found in commercial buildings, industrial plants, and medium-sized power plants. It balances power handling with safety. They are crucial in applications like motor control centers. They are also crucial in feeder circuits and distribution transformers.

Low-Voltage Switchgear (Up to 1kV)

These are more common. They are used in small-scale applications, such as houses and small businesses. They play a key role in protecting and controlling lower voltage power systems.

Types of Insulating Media in Switchgear

Air

Commonly used due to its cost-effectiveness but has a lower dielectric strength.

- Pros: It is cheap and available. It is non-toxic and eco-friendly. There is no risk of leaks or contamination.

- Cons: It has low dielectric strength. This requires larger equipment. It is affected by things like humidity and temperature.

Fluid (including oil)

Offers better insulation and cooling, suitable for systems prone to overheating. Oil is known for its high dielectric strength.

- Pros: Better insulating properties than air, cooling benefits, oil has high dielectric strength.

- Cons: Leaks could cause hazards. You need to do regular maintenance and monitor for leaks.

Gas (e.g., Sulfur Hexafluoride)

Pressurized gasses, like Sulfur Hexafluoride, have high dielectric strength. They are used in small Switchgear designs.

- Pros: Higher dielectric strength than air, non-flammable, chemically stable.

- Cons: It is more expensive than air. It needs special handling and safety precautions because it is a greenhouse gas.

Solid (e.g., resins)

Materials like resins offer excellent dielectric strength and are resistant to chemical and thermal deterioration.

- Pros: It has high dielectric strength. This allows compact designs. It is resistant to deterioration and performs consistently over a wide temperature range.

- Cons: More expensive, less flexible in application due to rigid nature.

Operational Mechanics of Switchgear

Process of Interrupting Power Flow

Switchgear detects faults, like overcurrents or short circuits. It quickly stops the power. This pause is crucial. It prevents damage to the electrical system and ensures safety.

Application in De-energizing Equipment for Maintenance

Switchgear is vital for safety. It allows for turning off equipment to maintain and fix it. This ensures that maintenance personnel can work safely. They can avoid the risks of live circuits.

Switchgear in Different Industrial Applications

Use in Motors, Feeder Circuits, and Power-Distribution Transformers

Switchgear is vital for safety. It allows for turning off equipment to maintain and fix it. This ensures that maintenance personnel can work safely. They can avoid the risks of live circuits.

Applications Across Various Industries

Switchgear is versatile. It is indispensable in many sectors, including manufacturing, energy, utilities, and healthcare. It can adapt to different voltages and configurations. This allows for its wide use in many settings.

Advanced Technologies in Switchgear Design

Innovations in Safety Features

Modern Switchgear designs have advanced safety features. They include fault detection algorithms, predictive maintenance, and better controls. These advancements significantly improve the safety and reliability of electrical systems.

Integration with Digital Control Systems

Digital technologies are integrated into Switchgear. They include IoT and smart monitoring. They allow for real-time data analysis and remote management. This digitalization enables predictive maintenance. It also improves energy efficiency and management of electrical systems.

Emerging Trends and Future of Switchgear

Sustainability and Efficiency

Looking forward, the Switchgear industry is moving towards more sustainable and energy-efficient solutions. This includes developing Switchgear. It integrates renewable energy sources. It also cuts the carbon footprint and improves efficiency.

Smart Grid and IoT Integration

The future of Switchgear lies in its integration with smart grid tech and IoT devices. This integration is expected to revolutionize Switchgear. It will offer better monitoring, predictive maintenance, and adaptability to changing power demands.

Recap

Importance and Evolution of Switchgear

Switchgear has changed a lot over the years. It is now a key part of modern electrical systems. Its role in ensuring the safety and efficiency of power systems is more crucial than ever.

Future Outlook

Ongoing technology advances will make Switchgear more integral. It will be key in the rapidly changing power distribution. Adapting to new challenges and innovations will continue to be key. It ensures safe and efficient electrical systems.

Understanding the Standards and Ratings for Switchgear

Manufacturers largely develop switchgear. They do this to innovate and tailor their products. But, to keep things safe, reliable, and compatible, it must follow industry standards. An exception is if alternative designs have been tested and proven effective.

Key Standards Governing Switchgear:

- IEEE (Institute of Electrical and Electronics Engineers): Provides comprehensive standards (such as IEEE C37 series) for different voltage levels of Switchgear, focusing on safety, design, and performance.

- IEC (International Electrotechnical Commission): Offers international standards like IEC 62271 for high-voltage Switchgear and IEC 61439 for low-voltage assemblies, ensuring global interoperability and safety.

- ANSI (American National Standards Institute): Develops standards (ANSI C37 series) that cover a range of Switchgear applications, emphasizing specifications for safe and efficient operation.

- NEMA (National Electrical Manufacturers Association): Sets guidelines (such as NEMA SG-5 for power Switchgear assemblies) for design, production, and testing, ensuring quality and consistency in the U.S. market.

Additional Codes and Standards:

- NEC (National Electrical Code): A part of NFPA 70, the NEC outlines safe electrical installation practices, including those for Switchgear, to prevent electrical hazards.

- NFPA (National Fire Protection Association): NFPA 70E focuses on electrical safety in the workplace, while NFPA 79 deals with electrical standards for industrial machinery, both impacting Switchgear use and safety.

- UL (Underwriters Laboratories): UL standards (such as UL 1558) provide safety-related certifications for Switchgear, ensuring the products meet rigorous safety and reliability criteria.

Importance of Standards:

- Safety and Reliability: Adhering to these standards ensures that Switchgear operates safely under various conditions, minimizing the risk of electrical hazards.

- Interoperability and Compatibility: Standards, like those from the IEC, promote global compatibility. They make it easier to integrate Switchgear from different makers.

- Innovation within Boundaries: Manufacturers are free to innovate. But, these standards ensure that new ideas don’t compromise safety and performance.

- Regulatory Compliance is essential. Manufacturers must follow them because they are legally required.

Our Low Voltage Switchgear

Spike Electric Low Voltage Switchgear is the new low voltage Switchgear platform. It has the best of both worlds. It has the state-of-the-art SACE® Emax® 2 air circuit breaker with SACE Emax 2 Ekip trip unit technology. These are built into the proven AKD Switchgear platform. This again shows the innovation and reliability. End users expect this from Spike Electric.

Spike Electric makes Low Voltage Switchgear in an ISO 9001 certified facility. It is built to tough standards.

Spike Electric makes Low Voltage Switchgear. It meets the demands of industry, utilities, and commerce. It is designed and tested in accordance with the latest IEEE C37.20.1 standard, CAN/CSA-C22.2 No. 31, and UL 1558 standards (file no. E76012). Spike Electric Low Voltage Switchgear has been conformance-tested to ANSI C37.51. Any equipment requiring UL 1558 or CSA labeling will be provided with a cUL label. A cUL label is a third-party certification. It shows the Switchgear meets ANSI/IEEE and CSA standards.)

ANSI/IEEE standards require that Switchgear operates at the ratings of devices installed. Switchgear short circuit ratings are based on two 30-cycle withstand tests. There is a 15-second interval between the two tests. They are performed at 15 percent power factor and 635 Vac maximum. In addition, ANSI/IEEE Switchgear tests the design for heat. This testing includes the UL 1066 Power Air Circuit Breaker. In contrast, switchboards only do a single 3-cycle withstand test at 20% power factor and 600 Vac max. They do not need thermally tested solutions with UL1066 or UL489 breakers.

Spike Electric Low Voltage Switchgear Switchgear is available with the following ratings:

- 600 Vac nominal, 635 Vac maximum

- 10000 amps AC main bus/6000 amps breaker max.

- 50/60 Hz

100 kA symmetrical short circuit

Our Metal-Clad Medium Voltage Switchgear

We are Spike Electric Controls. We specialize in designing and making state-of-the-art Metal-Clad Medium Voltage Switchgear. We adhere to the highest industry standards. We are committed to delivering cutting-edge Metal-Clad Switchgear solutions. They ensure reliability, efficiency, and safety in many industries.

Compliant with IEEE C37.20.2 Standards for Metal-Clad Switchgear

Spike Electric Medium Voltage Switchgear is manufactured in an ISO 9001 certified Spike facility and built to rigorous standards. Our Metal-Clad Medium Voltage Switchgear meets the strict requirements of IEEE C37.20.2. This shows our commitment to quality and technical excellence. Key features of our Metal-Clad Switchgear include:

- Optimal Voltage Range: Our Metal-Clad Switchgear operates well at 4.60 kV to 38 kV. This makes it suitable for many medium voltage uses.

- Our Metal-Clad Switchgear addresses various power demands. It offers main bus current ratings of 1200 A, 2000 A, 3000 A, and 4000 A. This range ensures it works with many electrical loads.

- Our Medium Voltage Switchgear has a safety-focused metal-clad design. It makes the gear safer and more durable. Its structure is divided into compartments. These isolate vital parts like instruments and connection points. This provides added protection and makes maintenance easier.

- Our Metal-Clad Switchgear has grounded metal barriers in each compartment. They enhance safety against electrical faults and add to the longevity and reliability of your power systems.

At Spike Electric Controls, we focus on pioneering solutions. We work in the realm of Metal-Clad Medium Voltage Switchgear. We are dedicated to providing products that meet our customers’ changing needs. They ensure that their electrical systems run efficiently and safely.

Our Medium Voltage Load Interrupter Switches

Spike Electric Controls is proud to present our Medium Voltage Load Interrupter Switches. They are expertly crafted to align with the pivotal IEEE C37.20.3 standards. We are committed to innovation and quality. This commitment is clear in every Load Interrupter Switch we make. These switches provide reliable and efficient solutions for your power management needs.

Adherence to IEEE C37.20.3 Standards

Spike Electric makes Medium Voltage Load Interrupter Switches. They are made in an ISO 9001 certified Spike facility. They are built to rigorous standards. Our Medium Voltage Load Interrupter Switches are engineered with precision. They comply with the critical specs of IEEE C37.20.3. This commitment ensures the highest standards of safety and functionality in our products. Key features of our Load Interrupter Switches include:

- Broad Voltage Range Compatibility: Our switches are designed to operate effectively across a wide voltage spectrum, from 2.4 kV to 38 kV. This versatility makes them fit for many uses. They work in many settings.

- Load Ratings for Diverse Requirements: They cater to many power system needs. They have load ratings of 600 A and 1200 A. These ratings ensure they work with many electrical loads and needs.

- Designed for Excellence: Each of our Medium Voltage Load Interrupter Switches complies with IEEE C37.20.3 standards. But, they aim to exceed them. This focus is on beating the benchmarks. It ensures our switches offer better performance and reliability.

At Spike Electric Controls, we know the critical role of Load Interrupter Switches. They are for Medium Voltage. They are key to the safety and efficiency of electrical systems. We are committed to quality and innovation. This commitment drives us to make products. They must not just meet but exceed industry and customer standards.

Our 4160V – 15kV Arc-Resistant Switchgear

We are at Spike Electric Controls. We are at the forefront of delivering Arc-Resistant Switchgear. Engineers design it to provide the highest level of safety in power systems. We design our Arc-Resistant Switchgear to handle and contain arcing faults. It protects both equipment and people.

Compliant with IEEE C37.20.7 Standards

We stick to the strict requirements of IEEE C37.20.7. This shows our dedication to safety and quality. This standard is a benchmark for testing metal-enclosed Switchgear. We rigorously test our products to meet it. Key features of our Arc-Resistant Switchgear include:

- We test under IEEE C37.20.7 guidelines. Our Arc-Resistant Switchgear undergoes thorough testing to IEEE C37.20.7. This testing ensures it can endure internal arcing faults. This testing is crucial. It certifies the Switchgear’s ability to handle tough faults.

- Rated for Up to 15 kV. It is robust and reliable. Our Arc-Resistant Switchgear can handle applications up to 15 kV. This makes it suitable for many medium voltage applications. Safety is crucial in these applications.

- Our Arc-Resistant Switchgear has a metal-enclosed design. It adds safety by protecting from internal arcs. The design also makes the equipment durable and long-lasting.

Spike Electric Controls: Synonymous with Reliability and Safety

At Spike Electric Controls, we understand the critical importance of safety. It’s key in electrical power management. It shows our dedication to solutions that keep your operations and personnel safe. Explore the world of enhanced electrical safety with Spike Electric Controls’ Arc-Resistant Switchgear. Contact us to learn more about our Switchgear solutions. Find out how we can help protect your electrical infrastructure. Choose Spike Electric Controls for Switchgear solutions where safety and reliability are non-negotiable.

Our 4160V – 15kV Safe Sync Medium Voltage Automatic Transfer Switch

Seamless Power Transition with Our Advanced Medium Voltage Transfer Switch

It is the Spike Electric Controls 4160V – 15kV Safe Sync. It is a pioneering solution for power continuity and reliability in medium voltage. This top-notch transfer switch is carefully designed. It ensures smooth power transitions in medium voltage systems. It improves the safety and efficiency of your power system.

Built to Metal Clad Switchgear Standards and UL 1008A

We commit to excellence. This shows in the switch’s strong design and construction. It is the Safe Sync Medium Voltage Automatic Transfer Switch. It follows the highest industry standards.

- Our transfer switch complies with the Metal Clad IEEE Switchgear standards. It ensures better protection and reliability. This compliance ensures that the switch meets tough requirements. They are on medium voltage power systems. It provides better safety and operational excellence.

- The Safe Sync Medium Voltage Automatic Transfer Switch has a UL 1008A Listing. This means it is UL listed for UL 1008A. The listing shows that it meets strict safety and quality rules. This UL listing shows the switch is reliable and performs well. It’s for critical power applications.

Key Features of the 4160V – 15kV Safe Sync Medium Voltage Automatic Transfer Switch

- Voltage Range: Our transfer switch is best for medium voltage. It works well at 4160V to 15kV. This range meets a broad set of power system needs.

- Automatic Operation: It’s engineered for automatic operation. The switch seamlessly switches power sources without manual intervention. This ensures continuous power and minimizes downtime during outages.

- The Safe Sync feature ensures safe synchronization. It makes the Switchgear sync safely between power sources. This reduces the risk of power surges or interruptions during the transfer.

Spike Electric Controls: Your Trusted Partner for Power Solutions

At Spike Electric Controls, we aim to innovate. Our innovations raise the standards for power management. Our 4160V – 15kV Safe Sync Medium Voltage Automatic Transfer Switch reflects our commitment. We deliver products that combine safety, efficiency, and reliability. Experience the advanced capabilities of the Safe Sync Medium Voltage Automatic Transfer Switch. Contact Spike Electric Controls to learn more. They can tell you more about how this product can improve your power systems. Trust us to empower your operations with cutting-edge electrical solutions.

Understanding 38kV Switchgear:

In the world of electrical power, switchgear is key. It manages, protects, and isolates circuits. Various types of switchgear are used across industries. The 38kV switchgear stands out. It can handle high-voltage tasks with much efficiency and safety. Here’s what you need to know about 38kV switchgear. It is a key player in managing electrical power systems.

The Heart of High-Voltage Electrical Systems

38kV switchgear is designed to operate with systems. They have voltage levels up to 38 kilovolts (kV) RMS. This type of switchgear is vital in places. They need strong electrical control and protection. These places include utility substations, industrial plants, and big data centers. The term “38kV” refers to the highest voltage the switchgear can handle. It also shows it is suitable for systems at common voltages like 35kV and 34.5kV. This makes it a versatile solution in the high-voltage world.

Built on Solid Standards

It adheres to the IEEE Standard. 38kV switchgear meets rigorous standards for safety, reliability, and performance. Following this rule ensures that the switchgear can handle high voltage. This includes electrical and mechanical stress.

- Rated Maximum Voltage: The switchgear can handle up to 38kV RMS. This is the power of systems at or below this voltage. It covers common voltages like 35kV and 34.5kV.

- Power Frequency Withstand: It has a rating of 80kV RMS. The 38kV switchgear is tested to endure continuous operational voltages. This ensures reliability under normal conditions.

- Lightning Impulse Withstand (BIL): The BIL rating of 150kV Peak is particularly crucial. It shows the switchgear’s ability to protect against brief voltages. These include lightning strikes and switching surges. The switchgear provides a high level of insulation. It safeguards the electrical system from sudden voltage spikes.

The Core of System Protection

38kV switchgear has various parts. These parts include circuit breakers, disconnect switches, and control instruments. They are all in a metal-clad enclosure. This metal-clad design ensures compartmentalization. It has grounded barriers for safety and easy maintenance. Features like automatic shutters and insulation cover the main circuit parts. They greatly reduce the risk of electrical faults.

Customization and Flexibility

The foundational standards set the stage. But, 38kV switchgear offers many ways to fit specific operational needs. Advanced protective relays are integrated. Adaptations are made for unique system voltages. The switchgear can be tailored to various applications. This ensures that each setup is optimized for performance and safety.

Ensuring Reliability and Safety in High-Stakes Environments

38kV switchgear is integral to maintaining the integrity of high-voltage electrical systems. This type of switchgear controls power flow. It also protects against overloads and allows for safe maintenance. It ensures that electrical systems run well, efficiently, and safely. This is true even under the most demanding conditions.

It powers large industrial complexes. It supports critical infrastructure and manages utility networks. 38kV switchgear is at the heart of high-voltage electrical systems. It offers unmatched reliability and protection.

Understanding 27kV Switchgear:

27kV switchgear is crucial in the world of electrical power distribution. It provides safety, efficiency, and reliability for medium-voltage applications. It is designed to manage, protect, and isolate electrical circuits. 27kV switchgear is vital in systems. They need precise control over medium voltages. Here’s a closer look at 27kV switchgear. It’s crucial for managing power in various settings.

Tailored for Medium-Voltage Excellence

27kV switchgear is made to operate in systems with a voltage up to 27 kilovolts (kV) RMS. This makes it ideal for many industrial, commercial, and utility uses. It is designed for systems at common medium voltages, like 24kV and 20kV. It is a versatile and effective solution for controlling power in these ranges.

Adherence to Rigorous Standards

27kV switchgear is built to meet IEEE Standard guidelines. The rules are strict. They ensure the safety, reliability, and integrity of each unit. This includes:

- Rated Maximum Voltage: It is 27kV RMS. The switchgear is designed to handle and manage the distribution of electrical power. It does this for systems at or below this voltage. This includes common voltages, such as 24kV and 20kV. They provide flexibility and reliability in many uses.

- Power Frequency Withstand: It has a rating of 60kV RMS. This shows that 27kV switchgear can withstand operational voltages. It does so without succumbing to electrical stress. This ensures consistent performance under standard conditions.

- Lightning Impulse Withstand (BIL): A BIL rating of 125kV Peak underscores the switchgear’s resilience against transient voltages. This protection level is crucial. It guards the system from external surges, like those from lightning. It also guards from internal voltage spikes. It ensures the long life and reliability of the electrical infrastructure.

The Critical Role in Electrical Systems

27kV switchgear has advanced components like circuit breakers and control instruments. They are housed within a secure metal-clad enclosure. The switchgear offers complete protection and control. This setup helps distribute power well. It also keeps the system safe. It does this by isolating faults and responding quickly.

Customizable for Specific Needs

27kV switchgear is modular. It allows for much customization. It meets the unique needs of different electrical systems. It can adapt to specific voltages. It can integrate protective devices. It can fit unique operations. 27kV switchgear can be tailored to work well with the system.

A Pillar of Medium-Voltage Distribution

27kV switchgear is key. It helps distribute power safely and efficiently in medium-voltage systems. It can manage electrical loads. It protects against circuit overloads. It enables safe maintenance and testing. These abilities make it a key part of modern electrical infrastructure.

It supports vital industrial processes. It also ensures the reliability of commercial power systems and more. 27kV switchgear is key. It keeps electrical networks stable and safe. It embodies the principles of versatility, reliability, and safety.

Understanding 15kV Switchgear:

15kV switchgear is a crucial part of medium-voltage electrical power systems. It offers a strong solution for managing, protecting, and isolating electrical circuits. It is tailored to work well within systems of up to 15 kilovolts (kV) RMS. This type of switchgear is pivotal in many applications. These range from industrial operations to utility distribution networks. Here’s an insightful look into what 15kV switchgear is. It’s important in the electrical landscape.

Designed for Medium-Voltage Mastery

15kV switchgear is designed for systems with voltages up to 15kV RMS. This makes it a versatile player in the medium-voltage arena. It’s great for common voltages like 11kV and 13.8kV. It offers a reliable platform for distributing and controlling power. It does so in these ranges.

A Testament to Rigorous Standards

It aligns with the strict IEEE Standard. 15kV switchgear follows critical rules. They ensure its ability to handle medium-voltage power with great reliability and safety. Key ratings include:

- The 15kV RMS rating is the rated maximum voltage. It shows the switchgear’s ability to handle and distribute electrical power. It can do this for systems at or below this level. This includes the common 11kV and 13.8kV systems. The switchgear does this with efficiency and reliability.

- The rating is for Power Frequency Withstand. It is 36kV RMS. The rating shows the switchgear’s resilience under operational voltages. It confirms the switchgear’s ability to sustain electrical performance without compromise under standard conditions.

- The switchgear has a Lightning Impulse Withstand (BIL) of 95kV Peak. It is fortified against transient voltages. This protects the system from both external and internal electrical surges. This level of insulation is vital. It protects the system against lightning and surges. It keeps the system reliable and running.

Core to Electrical System Safety and Efficiency

15kV switchgear has modern components. These include circuit breakers and disconnect switches. It also has advanced control systems. They are all in a secure, metal-clad enclosure. This setup is comprehensive. It enables efficient power distribution. It also ensures safety. It does this through quick fault isolation and responsive controls.

Versatility Through Customization

15kV switchgear has a modular design. It allows for much customization to fit specific needs and system requirements. It may involve adjusting to unique voltage needs. It may also involve using specialized protective devices. Or, meeting specific environmental conditions. 15kV switchgear can be set up to deliver great performance and meet high standards.

Pillar of Medium-Voltage Distribution

15kV switchgear is vital. It is used to distribute and control power in medium-voltage networks. It can efficiently manage electrical loads. It protects against overloads and aids safe maintenance. This makes it a key part of modern electrical infrastructure.

It powers essential industry. It ensures the reliability of power systems. 15kV switchgear supports the safety of medium-voltage electrical distribution. It shows the principles of efficiency, reliability, and protection.

Understanding 8.25kV Switchgear:

8.25kV switchgear is a crucial part of medium-voltage electrical systems. It is good at managing power. It protects and controls power flow with precision and safety. It is designed for systems up to 8.25 kilovolts (kV) RMS. It is well-suited for settings needing an in-between voltage level. It offers a custom solution for special electrical distribution and control needs.

Engineered for Specialized Applications

8.25kV switchgear is for applications where medium-voltages, like 6.6kV or 5kV, are not needed. It is also useful where system specs require a lower voltage for efficiency or safety. It bridges the gap between low-voltage and higher medium-voltage systems. It provides a tailored way to distribute power. This approach enhances system compatibility and efficiency.

Adherence to Exacting Standards

The switchgear follows the IEEE Standard. It stands at 8.25kV. The standard is strict. It guarantees the switchgear’s great performance and safety. These standards include:

- Rated Maximum Voltage: At 8.25kV RMS, this switchgear is specifically designed to function seamlessly within electrical systems operating at this voltage, ensuring reliable power distribution and control without exceeding operational thresholds.

- Power Frequency Withstand: The power frequency withstand rating of 36kV RMS underlines the switchgear’s capacity to endure normal operating voltages, affirming its durability and reliability under typical service conditions.

- Lightning Impulse Withstand (BIL) is 95kV Peak. This rating indicates strong protection from voltage spikes. This crucial feature shields the electrical infrastructure from damage. It protects from lightning strikes and switching surges. This helps to keep the system intact and running.

Integral to Specialized Electrical Systems

The 8.25kV switchgear has advanced tech components in a metal-clad enclosure. These include circuit breakers and disconnect switches. Sophisticated control systems complement them.

This approach ensures:

- Effective power distribution and safety.

- It also allows quick fault isolation and system adjustments.

Customization for Unique Needs

Electrical systems are versatile. The designers created the 8.25kV switchgear to be modular and adaptable. It allows for extensive customization. This ensures that each setup is well configured. It is set up to meet specific voltage, environmental, and protective needs. This enhances system performance and safety.

A Versatile Solution in Medium-Voltage Distribution

8.25kV switchgear is vital in specific medium-voltage electrical networks. It supports many applications with its unique voltage level. It provides a tailored solution that fits specific needs. It shows efficiency, reliability, and safety in power distribution and control.

It serves niche industries, augments utilities, or meets commercial power needs. 8.25kV switchgear is crucial for managing power safely and well. It embodies the essence of precision-engineered power solutions.

Understanding 4.76kV Switchgear:

4.76kV switchgear is a key part of the electrical distribution framework. It is made for low-to-medium voltage applications. Engineers design 4.76kV switchgear to help control, protect, and isolate electrical circuits. It plays a key role in improving the efficiency and safety of many electrical systems.

Bridging Low and Medium Voltage Requirements

It is designed to work smoothly at voltages up to 4.76 kilovolts (kV) RMS. 4.76kV switchgear is critical at many voltage levels, including 1.2kV, 2.4kV, 3.3kV, 4.16kV, and up to 4.76kV. Its adaptability makes it ideal for many installations. It is used in industrial facilities, commercial complexes, and utility substations. It is a versatile solution for a diverse range of electrical power needs.

Ensuring Safety and Performance Through Standards

The 4.76kV switchgear follows the strict IEEE Standard. It meets and exceeds the criteria for safety, reliability, and performance. These criteria include:

- Rated Maximum Voltage: With a 4.76kV RMS rating, this switchgear is designed for optimal operation within electrical systems functioning at or below this level, facilitating reliable power distribution and control across common lower voltage applications.

- Power Frequency Withstand: A power frequency withstand rating of 19kV RMS underscores the switchgear’s capability to maintain structural integrity and operational reliability under normal voltage conditions, ensuring the system’s resilience.

- Lightning Impulse Withstand (BIL): With a BIL rating of 60kV Peak, the switchgear offers formidable protection against transient voltage disturbances. This critical protection mechanism is essential for safeguarding the electrical infrastructure against potential damages from external surges, including lightning strikes, thereby enhancing system durability and continuity.

A Linchpin in Electrical Distribution

It has leading-edge components. These include circuit breakers, disconnect switches, and advanced monitoring systems. They are in a robust, metal-clad enclosure. 4.76kV switchgear ensures comprehensive control and safety. This integration supports efficient power distribution. It also enables fast fault detection and isolation. This helps responsive system management.

Tailored Solutions for Diverse Applications

The switchgear is modular and customizable. It meets specific requirements and challenges. This ensures that each configuration fits its application well. 4.76kV switchgear can be tailored to unique conditions. It fits specific voltages and includes protection. This tailoring affirms its role as a flexible power solution.

The Foundation of Reliable Power Distribution

It holds a critical spot in the electrical distribution hierarchy. 4.76kV switchgear supports the reliability and safety of low-to-medium voltage networks. It can efficiently manage electrical loads. It also has robust protection against overloads and faults. These traits make it indispensable. They are key for ensuring the smooth operation of electrical systems.

It powers vital industrial processes. It also keeps commercial and utility power systems working. 4.76kV switchgear shows the essence of precision. It also shows reliability in power distribution and control. It is a key milestone in the journey to safer electrical infrastructure.

Common Voltages in Medium Voltage Metal Clad Switchgear

MV Metal Clad Switchgear is a key part. It is of electrical distribution systems. It connects high-voltage transmission lines to the low-voltage needs of end users. This equipment is essential. It is needed for the safe and efficient distribution of electricity. It goes to various sectors, including industrial, commercial, and utility networks.

MV Metal Clad Switchgear is designed to operate at a range of voltage levels. Each level is for specific applications. They are based on power needs, distance, and efficiency. Here’s a breakdown of the most common voltages and their typical uses:

- 1,200V to 5kV Range: This voltage spectrum is particularly favored in heavy industrial settings where large motors and drives are prevalent. It supports high-power applications where efficiency and space considerations render lower voltages impractical.

- The 6.6kV to 15kV range is widely utilized in both industrial and utility applications because they choose voltages within this range for their balance between equipment size and power capacity. They are common in sectors such as mining, marine, and large-scale commercial facilities.

- Above 15kV: Voltages exceeding 15kV up to 38kV cater to extensive industrial complexes and utility distribution networks. These higher voltages make power easier to transmit. They are better for long distances and have few losses. They make power grids reach farther and work better.

Specific requirements determine the choice of each MV voltage level. These include the type of the electrical load. They also include the layout of the distribution network and the operational environment. Engineers can pick the right voltage for an application. This keeps electrical systems safe and efficient. It cuts losses and boosts performance.

| Rated Maximum Voltage (kV rms) | Common Applications | Power Frequency Withstand (kV rms) | Lightning Impulse Withstand (BIL) (kV peak) |

| 1,200V (1.2kV) | Heavy industrial applications for large motors and drives. | 19 | 60 |

| 2,400V (2.4kV) | Industrial and commercial distribution, large HVAC systems, pumping stations. | 19 | 60 |

| 3,300V (3.3kV) | Mining industry, heavy industrial applications, especially underground. | 19 | 60 |

| 4,160V (4.16kV) | Industrial plants, power generation, utility distribution. | 19 | 60 |

| 4,760V (4.76kV) | Industrial and utility distribution. | 19 | 60 |

| 5kV (5,000V) | Large industrial applications, manufacturing facilities, oil and gas plants. | 36 | 95 |

| 6.6kV (6,600V) | Heavy industry with large electric motors, marine and mining sectors. | 36 | 95 |

| 11kV (11,000V) | Primary urban and rural power distribution, large industrial supply. | 36 | 95 |

| 13.2kV (13,200V) | North American distribution networks, medium to large industrial consumers. | 36 | 95 |

| 13.8kV (13,800V) | Utility distribution in urban/industrial settings, large facility distribution. | 36 | 95 |

| 15kV (15,000V) | Similar to 13.8kV, for utility distribution and in large industrial plants. | 36 | 95 |

| 15.5kV (15,500V) | Certain distribution networks, slightly above standard MV range. | 60 | 125 |

| 22kV (22,000V) | Regional power distribution to bridge high-voltage transmission and local MV distribution. | 60 | 125 |

| 24.9kV (24,900V) | Primary utility distribution in North America, urban and rural areas. | 60 | 125 |

| 25kV (25,000V) | Railway electrification, especially for high-speed rail networks. | 60 | 125 |

| 27kV (27,000V) | Specialized industrial applications, higher load utility distribution. | 60 | 125 |

| 33kV (33,000V) | Regional utility distribution, rural/suburban areas. | 80 | 150 |

| 34.5kV (34,500V) | Industrial complexes, utility distribution in North America. | 80 | 150 |

| 35kV (35,000V) | Large industrial applications, utility distribution networks. | 80 | 150 |

| 36kV (36,000V) | Specialized utility and industrial settings. | 80 | 150 |

| 38kV (38,000V) | Regional utility distribution, large industrial plants/data centers. | 80 | 150 |

American-Made Excellence: Our Commitment to the Build America Buy American Act

At Spike Electric, we take pride in making switchgear solutions. They are at the forefront of tech innovation. They are also deeply rooted in our commitment to American manufacturing excellence. The Build America Buy American Act aims to boost American industry. It does this by requiring federally funded infrastructure projects to use American-made products. We are a top provider of switchgear solutions. They meet and exceed these requirements.

Why Choose American-Made Switchgear?

Our switchgear solutions are made in the United States. They adhere to the highest standards of quality and reliability. The BABA Act stresses using American-made iron, steel, and products and construction materials. This is a standard that Spike Electric not only meets but proudly champions (U.S. Department of Commerce) (The Department of Energy’s Energy.gov).

Supporting Local Economies: By choosing our American-made switchgear, you get a great product. You also support the American economy, protect local jobs, and help build a sustainable manufacturing sector. This sector is vital for the nation’s infrastructure (Rural Development).

Compliance and Standards: Spike Electric follows the BABA Act. It ensures that our products are not just made in America. They also embody the spirit of American innovation and craftsmanship. Our switchgear solutions meet the tough standards of the IEEE, ANSI, and UL. They ensure that you get safe, efficient products. They are ready to meet the needs of today and tomorrow (U.S. Department of Commerce) (The Department of Energy’s Energy.gov) (Rural Development).

Our Pledge to You

Spike Electric is dedicated to following the Build America Buy American Act. They provide switchgear for infrastructure projects across the nation. Their solutions are built on the foundation of American excellence. You may be involved in utility, industrial, or commercial projects. We are committed to US manufacturing. It ensures that you get products with unmatched quality, reliability, and performance.

Choose Spike Electric for your switchgear needs. See the difference that American-made quality brings to your projects.

Cole Attaway

CEO

Robert Hudson

President

About Spike Electric Controls

Spike Electric Controls is based in the lively city of Houston, Texas. It is a well-known maker of custom electrical gear for the energy sector. We specialize in rapidly making complex and integrated power distribution and control systems. They are made to meet the critical needs of our clients. We have a wide product range. It goes from the simple "Switchrack" to the complex "Medium Voltage Switchgear". Our team of seasoned experts crafts these products. They are committed to meeting your specific application and design needs.

At the core of our operations, safety takes precedence. We move assembly from busy job sites to our secure facility. This cuts the injury risk for our clients. This move also helps improve our quick ship products. They are delivered complete and come with thorough quality assurance documentation. Our fast delivery service has many advantages. It leads to less downtime and better efficiency.

Clients benefit from our all-encompassing, integrated service approach. This approach includes: consulting, solving technical issues, and innovating solutions for outdated equipment. It also includes managing your custom-engineered solutions. It has field startup support and constant emergency assistance.

Spike solutions minimize unplanned downtime. They also reduce the need for overtime and boost efficiency. Spike Electric Controls has many facilities and much expertise. It is well-equipped to manage your electrical product needs. We take pride in our in-house metal shop. It lets us modify or make structures for your orders. Our panel wiring facility is climate-controlled and ISO 9001 Certified. Our team focuses on building quality products there. We are committed to delivering great value to our customers. We do this by making products and systems. They operate with the highest safety standards and are very efficient in operation and design. Our record of repeat customers and longstanding relationships shows our commitment. It is a testament to our quality and service. We pride ourselves on being more than a supplier — we are a trusted partner in our clients' success.

Spike Electric operates 24 hours a day, six days a week. In 2021, we chose to close on Sundays to give our team a day for rest and worship. Still, we are always ready to help our customers with urgent needs. We offer support when it's most crucial.