WHAT IS A SWITCHBOARD?

Explore Switchboards & the Value of A Custom Switchboard Manufacturer

Table of Contents

- The Critical Role of Switchboards in Electrical Systems

- Understanding Electrical Switchboards

- Technical Specifications and Standards

- Types of Switchboards

- Service Entrance Switchboards: A Closer Look

- Comparative Analysis: Switchboards vs. Panelboards

- Advanced Switchboard Technologies and Solutions

- Installation Guidelines and Safety Protocols

- Custom Solutions and Emerging Trends in Switchboard Technology

- Importance of Switchboards

- Choosing a Switchboard Manufacturer

- UL 891 Switchboards

- Do Switchboards Use Copper or Aluminum Bus Bars?

- About Spike

The Critical Role of Switchboards in Electrical Systems

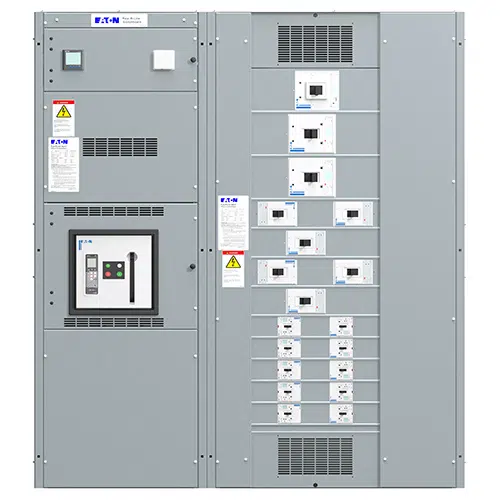

The switchboard is part of modern electrical systems. It is a key component. It organizes the efficient distribution and management of electricity. Switchboards are vital for safe and effective electrical infrastructures. They are found in busy commercial centers and heavy-duty industrial settings. This detailed guide aims to explain switchboards. It offers insights into their function. It shows their importance and many uses in our modern electrical systems.

Understanding Electrical Switchboards

A switchboard is a key assembly. It plays a critical role in an electrical distribution system. It divides an power feed into many branch circuits. Each circuit has a breaker or fuse. They are in a common enclosure. This distribution and protection are vital. They prevent electrical overloads and keep electrical networks safe.

The history of switchboards shows advances in electrical technology. Switchboards had rudimentary designs in the early days of electricity. They have transformed significantly into today’s sophisticated, digitally integrated systems. This change reflects the rising complexity and demands. They are in electrical distribution in many sectors.

Technical Specifications and Standards

Switchboards are designed with specific technical specifications to meet diverse needs. Typically, they have a max voltage rating of up to 600 Vac/Vdc. They can handle a bus rated up to 6000 A. These specs are crucial for choosing a switchboard for a particular use.

Following safety and operational standards is key. Examples include UL891 and NEMA Standard PB2. These standards are vital in designing and making switchboards. These standards ensure that switchboards are reliable and safe. They also ensure that switchboards can handle modern electrical systems. They set the benchmark for quality and safety. They provide guidelines for makers and reassurance for users.

Types of

Switchboards

General Purpose Switchboards

These are the most versatile and widely used types of switchboards. They often include molded case circuit breakers, metering, and surge protection. This makes them right for a broad range of uses. General purpose switchboards do many things. They start with basic power distribution. But, they can also do complex control and monitoring of electrical circuits.

Fusible Switchboards

Designed primarily for commercial and industrial applications, fusible switchboards are robust and reliable. They have a switching contact structure with an instant trip element. This provides better protection for feeder and branch circuits. These switchboards are valued in settings where circuit isolation and protection are crucial. For a Fused Switchboard, it is common to see fuses on the load side of a main breaker. This increases the system’s protection and makes it easy to isolate the bus. You can lock out the main breaker, then safely disconnect and replace the fuses when needed.

Commercial Metering Switchboards

These switchboards combine circuit breakers, chassis, and surge protection. They come in a single assembly for efficient multi-metering. They are key in places like shopping centers and office buildings. Individual metering is vital for accurate billing and energy management.

Service Entrance Switchboards: A Closer Look

Service entrance switchboards are the primary point of power entry in smaller facilities. They play a key role. They manage the first distribution of power from the utility. They must meet specific standards for safety and function. Compliance with local utility requirements is a key part of their design.

Comparative Analysis: Switchboards vs. Panelboards

Switchboards and panelboards serve similar functions in an electrical system. But, there are notable differences between them. Panelboards are usually limited to 1200 A max. They are designed for wall-mounting or flush-mounting. Switchboards, in contrast, are freestanding units with more capacity. They can handle up to 6000 A bussing and offer more access flexibility.

Advanced Switchboard Technologies and Solutions

Switchboard technology is always evolving. Innovations aim to improve functionality and user experience. For example, draw-out molded case switchboards are a boon. They are vital in places like healthcare and data centers. Their draw-out capability allows for quick breaker replacement, significantly reducing system downtime.

Integrated Facility System (IFS) switchboards represent another leap forward. IFS solutions integrate switchboards with other electrical systems. These systems include transformers and power supplies. This integration optimizes space and installation time. This integration is especially helpful in sectors like retail and construction. Efficiency and space use are key in these sectors.

Installation Guidelines and Safety Protocols

Proper installation and following safety rules are crucial. They are needed for switchboards to work well. Best installation practices include placing things strategically. This makes them easy to access and maintain. They must also follow local electrical codes and standards. Modern switchboards have safety features. These include surge protection and meters. They are vital for preventing electrical hazards and ensuring the system’s longevity.

Custom Solutions and Emerging Trends in Switchboard Technology

Being able to customize switchboards is a big advantage. They can be tailored to meet specific industrial and commercial needs. This customization covers the size and capacity of the switchboard. It also includes adding advanced control and monitoring systems.

Looking ahead, the future of switchboard technology is intertwined with the broader trends in electrical distribution and smart grid systems. Innovations are likely to focus on sustainability, energy efficiency, and integration with renewable energy sources. The increasing use of digital technologies and IoT (Internet of Things) in switchboards is set to revolutionize how power distribution is managed and monitored.

Importance of Switchboards

Electrical switchboards are indispensable components in modern power distribution networks. Their ability to manage and distribute electricity safely and efficiently is crucial. They need this skill in many commercial and industrial settings. This guide shows the importance of understanding switchboards. It covers their types and installation. It highlights their key role in safely and efficiently distributing electrical power.

Switchboard Protection with Protection Relays

Switchboards are crucial in power distribution. They manage the flow of electricity from the main feeder to branch circuits. To keep this critical infrastructure safe and reliable, switchboards often include protection relays. These smart devices serve as guards. They monitor and respond to dangers, protecting both equipment and people.

Types of Protection Relays

Protection relays come in various forms, each tailored to address specific threats:

-

- Overcurrent Protection Relays: These relays detect and respond to excessive current flow, preventing damage to cables and equipment caused by overloads or short circuits.

- Short-Circuit Protection Relays: Reacting with lightning speed, these relays isolate short circuits, minimizing the damage caused by these sudden surges of current.

- Ground Fault Protection Relays: Vigilantly monitoring for imbalances between the hot conductor and the ground, these relays safeguard against ground faults, preventing electrical shocks and potential fires.

- Arc Flash Protection Relays: These relays act swiftly to extinguish arc flashes, preventing severe burns and potential explosions caused by these intense electrical discharges.

Benefits of Protection Relays

Integrating protection relays into switchboards offers a multitude of benefits:

Integrating protection relays into switchboards offers a multitude of benefits:

-

- Enhanced Safety: Protection relays provide an extra layer of defense against electrical hazards, safeguarding personnel and equipment from harm.

- Improved Reliability: By promptly detecting and isolating faults, protection relays minimize downtime and maintain the uninterrupted flow of electricity.

- Reduced Maintenance Costs: By preventing equipment damage, protection relays lower maintenance costs and extend the lifespan of switchboard components.

In conclusion, protection relays are critical. They guard switchboards. They ensure the safety, reliability, and longevity of this vital power infrastructure.

Choosing a Switchboard Manufacturer

Warranty & Liability

When choosing a switchboard manufacturer, you must consider their warranties and liability. Look for manufacturers who establish direct relationships with reputable circuit breaker manufacturers. This is crucial to avoid any gray market components, which can be unreliable and unsafe. Most switchboard OEMs source their circuit breakers from leading companies. These include ABB, Eaton, Square D, and Siemens. The OEMs integrate these high-quality components into their systems.

A credible manufacturer should offer a warranty on the whole assembly. This warranty assures the quality and safety of their product. Moreover, they should provide evidence. The evidence should show the breakers are from major manufacturers. This would ensure a valid pass-through warranty. This guarantees the part’s quality. It also protects you from legal and safety issues due to bad parts.

UL 891 Certification

The UL 891 standard is a critical benchmark for safety in switchboard manufacturing. A UL 891 certification means a manufacturer passed tough testing by Underwriters Laboratories (UL). It shows that their switchboards meet strict safety rules. Be cautious of manufacturers who got this certification just for marketing. They lack a history of UL-listing their products.

Choose a manufacturer with UL 891 certification. They must actively list their panels under this standard. This ensures you get a product that meets high safety and performance criteria. This certification is not just a badge of honor. It is also a testament to the manufacturer’s commitment to safety and reliability.

ISO 9001 Certification

ISO 9001 certification is a testament to a manufacturer’s commitment to quality management. This standard is recognized worldwide. It ensures that the company follows a systematic approach to managing quality and making it better. A switchboard manufacturer has ISO 9001 certification. They are likely to have firm procedures for ensuring the quality and consistency of their products. This certification is a strong indicator. It shows a manufacturer’s dedication to making high-quality, reliable switchboards. They must meet customer requirements consistently.

In-house Fabrication Capabilities

Opt for a switchboard manufacturer with in-house metal fabrication and copper manufacturing capabilities. Manufacturers who manage these processes in-house have better control. They have control over the quality and timeliness of their products. Outsourcing these parts can lead to delays and quality issues. This is especially true if there are warranty or replacement needs. Manufacturers have in-house capabilities. They are better equipped to ensure the integrity and longevity of their switchboards. This provides you with a more reliable and consistent product.

Engineering Expertise

The presence of a well-qualified, in-house engineering team is a key factor. It is important when choosing a switchboard manufacturer. The team has degrees in engineering. They show the manufacturer’s commitment to technical excellence and innovation. This expertise isn’t just about making a product. It’s about ensuring the switchboard meets specific needs and challenges. An experienced engineering team can help a lot. They support with design customization. They also help with post-installation troubleshooting. This ensures a smooth and good experience for the customer.

UL 891 Switchboards

UL 891 Switchboards are vital electrical devices. They ensure the safe and efficient spread of power in businesses and factories. The switchboards adhere to the UL 891 standard. They are known for their high safety and quality. This makes them a reliable choice for managing electrical circuits.

These switchboards are robust. They can handle various electrical capacities, often up to 6000 Amps. They work for circuits up to 600V. They are built to withstand short circuit currents up to 2000A. This makes them very flexible. They can meet the needs of many electrical systems.

The design of UL 891 Switchboards focuses on user safety and ease of maintenance. They usually include features. These features are things like circuit breakers and fusible switches. They are for effective circuit protection. The switchboards adhere to UL standards. OSHA and the U.S. federal government ratify these standards. They make the switchboards safe. That’s why the boards are a top choice in places where electrical safety is key.

UL 891 Switchboards often face tough tests. They include tests for fault currents. These tests ensure they can handle intense stress. This testing reassures users of their durability and reliability in various operating conditions.

In addition to their technical capabilities, these switchboards often come with design flexibility. They can be customized to fit specific needs. They offer options in NEMA configurations. They also have integrated components like transfer switches, metering, and surge protectors. This customization ability has many uses. It spans from basic power distribution to complex control of electrical circuits.

UL 891 Switchboards are safe, reliable, and adaptable. They are a key part of modern electrical systems. They comply with strict standards. They have many design options. This makes them suitable for many industrial, utility, and commercial uses.

Industry Confusion & Terminology Differences when Describing a Switchboard

At times, they ask for a Switchboard when they want a different type of power gear. Below we have defined some of these key differences to help you decide which system fits your needs.

| Feature | Residential Load Centers | Panelboards | Switchboards | Switchgear |

| Application | Single-family homes, apartments, small commercial buildings | Commercial buildings, industrial facilities | Large commercial and industrial facilities, power distribution substations | Power distribution and control in power plants, substations, and industrial facilities |

| Voltage | Up to 240V | Up to 600V | Up to 1000V | Up to 600V |

| Current | Up to 100A | Up to 6,000A | Up to 6,000A | Up to 10,000A |

| Enclosure | NEMA 1 or 3R | NEMA 1 or 3R | Indoor or outdoor | Indoor or outdoor |

| Construction | Metal or plastic | Metal | Metal | Metal |

| Size | Small | Medium | Large | Extra Large |

| Components | Circuit breakers, fuses, ground bars | Circuit breakers, fuses, ground bars, metering devices | Circuit breakers, fuses, ground bars, metering devices, busbars | Circuit breakers, fuses, ground bars, metering devices, busbars, protective relays |

| Protection | Overcurrent protection, short-circuit protection | Overcurrent protection, short-circuit protection, ground fault protection | Overcurrent protection, short-circuit protection, ground fault protection, arc flash protection | Overcurrent protection, short-circuit protection, ground fault protection, arc flash protection, differential protection |

| Ul Listing | Ul 67 | UL 67 | UL 891 | UL 1558 |

| UL Listing Circuit Breaker | UL 489A or uL 1077 | UL 489 | UL 489 | UL 1066 |

| Cost | Least expensive | More expensive than residential load centers | More expensive than panelboards | Most expensive |

| Maintenance | Easy to maintain | Easy to maintain | Requires regular maintenance | Requires specialized maintenance |

| Mounting | Wall Mounted | Wall Mounted | Floor Mounted | Floor Mounted |

| Access | Front Access | Front Acess | Front & Rear Access | Front & Rear Access |

Additional notes:

- Residential load centers are typically used to distribute power to individual branch circuits in a home.

- Panelboards are typically used to distribute power to multiple branch circuits in a commercial or industrial building.

- Switchboards are typically used to control and protect main feeders and branch feeders in a commercial or industrial building.

- Switchgear is typically used to control and protect high-voltage power circuits in power plants, substations, and industrial facilities.

Do Switchboards use Copper or Aluminum Bus Bars?

UL 891 Switchboards can use either copper or aluminum bus bars. The choice of material depends on the specific requirements of the application.

- Copper bus bars are more expensive than aluminum bus bars, but they offer several advantages. Copper has a higher conductivity than aluminum, so copper bus bars can carry more current for a given size. Copper is also more resistant to corrosion than aluminum, so copper bus bars are better suited for applications where there is a risk of exposure to moisture or chemicals.

- Aluminum bus barsare less expensive than copper bus bars, but they also have some disadvantages. Aluminum has a lower conductivity than copper, so aluminum bus bars must be larger than copper bus bars to carry the same amount of current. Aluminum is also more susceptible to corrosion than copper, so aluminum bus bars may require additional protection in applications where there is a risk of exposure to moisture or chemicals.

The bus bar joints in a UL 891 Switchboard must be plated. They can use silver or tin. This protects them from corrosion, no matter the material used. Silver plating is the most common choice. It gives great corrosion protection and improves joint conductivity. Tin plating is a less expensive option, but it is not as corrosion-resistant as silver plating.

Here is a table showing the key differences between copper and aluminum bus bars. It includes the need for plating for corrosion resistance.

| Feature | Copper | Aluminum |

| Cost | More expensive | Less expensive |

| Conductivity | Higher | Lower |

| Corrosion resistance | Higher | Lower |

| Weight | Heavier | Lighter |

| Application | High currents, corrosion resistance | Cost, weight |

| Joint plating | Silver or tin plating required | Silver or tin plating required |

Switchboards From Spike

ABB Reliagear™ Switchboard

The GE Spectra Series Switchboards

All Spike UL 891 Switchboards

Cole Attaway

CEO

Robert Hudson

President

About Spike Electric Controls

Spike Electric Controls is based in the lively city of Houston, Texas. It is a well-known maker of custom electrical gear for the energy sector. We specialize in rapidly making complex and integrated power distribution and control systems. They are made to meet the critical needs of our clients. We have a wide product range. It goes from the simple "Switchrack" to the complex "Medium Voltage Switchgear". Our team of seasoned experts crafts these products. They are committed to meeting your specific application and design needs.

At the core of our operations, safety takes precedence. We move assembly from busy job sites to our secure facility. This cuts the injury risk for our clients. This move also helps improve our quick ship products. They are delivered complete and come with thorough quality assurance documentation. Our fast delivery service has many advantages. It leads to less downtime and better efficiency.

Clients benefit from our all-encompassing, integrated service approach. This approach includes: consulting, solving technical issues, and innovating solutions for outdated equipment. It also includes managing your custom-engineered solutions. It has field startup support and constant emergency assistance.

Spike solutions minimize unplanned downtime. They also reduce the need for overtime and boost efficiency. Spike Electric Controls has many facilities and much expertise. It is well-equipped to manage your electrical product needs. We take pride in our in-house metal shop. It lets us modify or make structures for your orders. Our panel wiring facility is climate-controlled and ISO 9001 Certified. Our team focuses on building quality products there. We are committed to delivering great value to our customers. We do this by making products and systems. They operate with the highest safety standards and are very efficient in operation and design. Our record of repeat customers and longstanding relationships shows our commitment. It is a testament to our quality and service. We pride ourselves on being more than a supplier — we are a trusted partner in our clients' success.

Spike Electric operates 24 hours a day, six days a week. In 2021, we chose to close on Sundays to give our team a day for rest and worship. Still, we are always ready to help our customers with urgent needs. We offer support when it's most crucial.