Spike Electric Modular Switchrack™

Benefits of Modular Switchracks™

Modular switchrack™ construction with Spike Electric sidesteps the possibility unproductive staff. We construct each modular element on-site at our facility, assuring a centralized, controlled product.

If you are not familiar with this process, here are the benefits of a modular switchrack™ solution with Spike Electric:

Faster

Modular switchrack™ construction with Spike Electric sidesteps the possibility unproductive staff. Additionally, the reduction in construction time can significantly save on construction financing costs. In many instances, prefabrication takes less than half the time when compared to traditional construction.

Less Expensive

You can expect significant savings due to the ability to progress work as a parallel operation in our factory and on your construction site. Significant cost savings on concrete slab foundation and hiring a civil engineer.

Better Quality

Factory tolerances and workmanship is of a higher quality and consistency to that achieved on site. Since prefabricated construction occurs in a controlled manufacturing environment and follows specified ISO 9001 standards, the sub-assemblies of the structure will be built to a uniform quality.

Safer

Since sub-assemblies are created in a factory controlled environment utilizing dry materials, there is less risk for problems associated with moisture, environmental hazards and dirt. Also, an indoor construction environment presents considerably fewer risks for accidents and other liabilities.

Switchracks: Industrial Applications

Free-Standing Switchrack Assemblies are used in multiple scenarios. They are used outdoors and indoors, and they are also used:

- To provide a complete motor control center in one integrated package

- In damp, wet or corrosive locations such as sewage treatment plants, lumber mills, marine installations, and food preparation areas

- In areas made hazardous due to the presence of flammable vapors or gases, such as petroleum refineries, chemical and petrochemical plants, gas gathering plants, pipeline compressor stations, and drilling rigs, both onshore and offshore

- In areas where hazardous dusts are present, such as coal handling facilities, grain processing and handling plants, and certain food process industries

Electrical switchracks provide a complete motor control center in one integrated package.

Why Choose A Spike Electric Modular Switchrack Assembly

Spike Electric provides the quickest delivery of the highest quality manufactured electric gear. We interact with our customers with high-quality customer service. That means you get:

- Two-Week Turnarounds (or faster) on Most Orders

- High Quality Manufacturing

- High Quality Customer Service

- A Manufacturing Parter for Years to Come

How does that translate into value for you? That’s simple.

Working with Spike Electric Controls means:

- Reduced Downtime

- Less Overtime for Your Staff

- Greater Operational Efficiencies

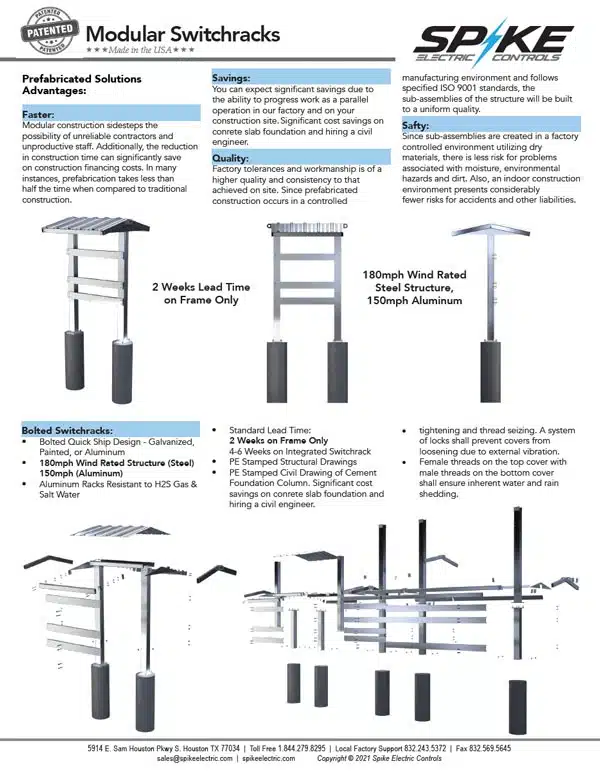

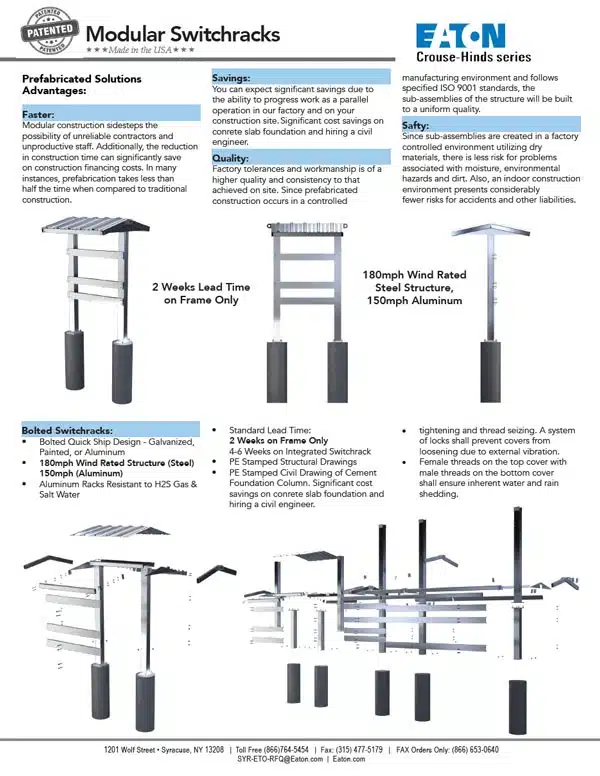

Switchrack 3D Renderings

Take a quick look at a 3D rendering of one of our electrical switchracks. These switchracks serve well in industrial scenarios, such as oil refineries. To learn more, call us or read our blog on the benefits of switchracks for refineries.