Products

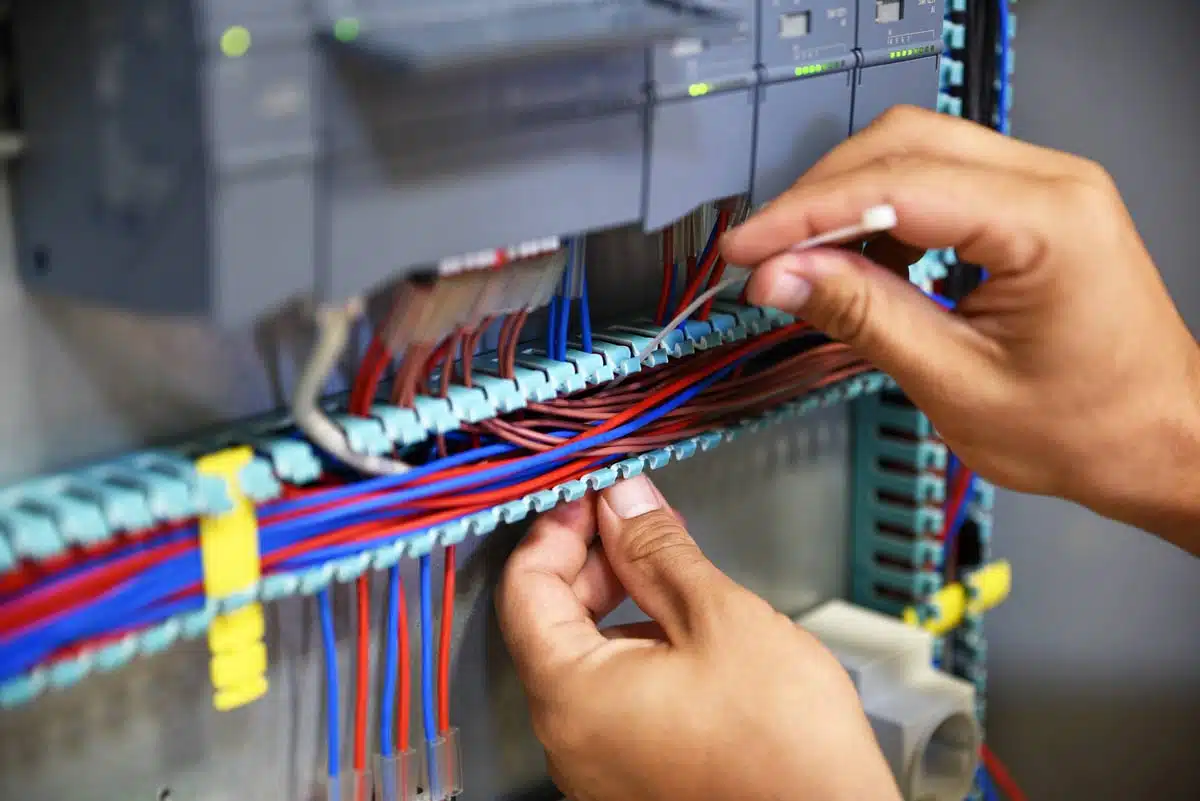

Safety doesn’t happen by accident. At Spike, we’re continually implementing safer processes to protect employees (yours and ours), educating our customers and partners on best practices and engineering solutions to create a safer world for everyone. Our core goal has always been to have the best delivery date on our clients electrical equipment, what will never be compromised is the safety of our staff that always transitions over to the safety of our clients.

Why Choose Spike?

Our Expertise

Globally certified hazardous location manufacturer.

Competitive Strategy

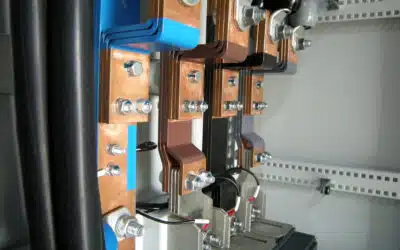

Providing custom-engineered power solutions gives our clients a competitive advantage.

Quality Care

We are dedicated to providing customers 24/7 emergency service.

Stock & Quick Ship Equipment

Largest Eaton Crouse Hinds Hazardous Location inventory in North America.

State-of-the-Art Engineering

Newer, faster, safer, more cost-effective product development is a priority to our design engineering team.

In-House Capabilities Minimize Risk

Our fabrication capabilities allow us to have complete control over the product output, ensuring a 99% on-time delivery record.

Reverse Engineering Obsolete Gear for Retrofits and Upgrades Is Our Specialty

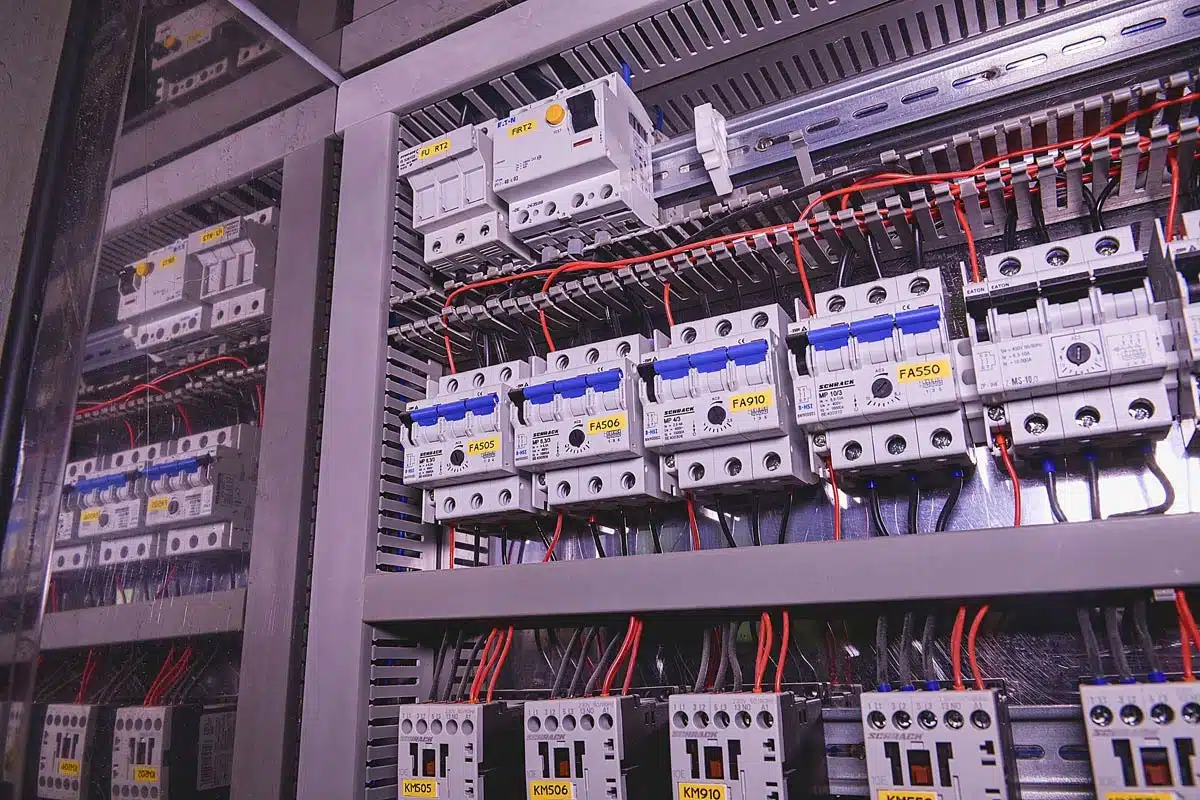

If a facility has been in operation with the same MCC, Switch Gear or Automation System for several years, chances are it is missing out on some of the advances in electrical technology. Fortunately, that does not mean the whole system needs to be replaced in order to bring the facility up to speed. Retrofitting is one solution.

Our Impact in Numbers

Safe Hours with No Lost Time Incidents

%

Customer Satisfaction

%

Yearly Increase for New Product R&D

Latest Articles

Why Most Switchgear Upgrade Quotes Miss the Mark—And How to Get It Right

Not all switchgear quotes are created equal. In fact, most quotes you’ll get from general contractors or service firms leave out critical...

Top Questions We Hear From Local Refineries During Switchgear Upgrades

Every week, we hear from refinery engineers, maintenance leads, and procurement teams who are trying to solve tough switchgear issues—and they...

Does Your Switchgear Pass Modern Safety Standards? Here’s How to Find Out

Many industrial facilities operate with switchgear that was installed 20, 30, or even 40 years ago—gear that may have been safe and compliant...

Do I Need a Breaker Compartment Adapter? Here’s What You Need to Know

Modern breakers are built for new technologies, updated safety standards, and faster response times—but that means they often don’t fit into...

What Is a Switchgear Retrofit—and When Does Your Facility Need One?

Retrofitting switchgear is a cost-effective way to modernize outdated systems without ripping out and replacing entire electrical lineups. But...

Understanding IEEE C37.59-2018: An Introduction to Power Switchgear Conversion

When it comes to electrical infrastructure, reliability, safety, and compliance are paramount. Organizations across industries rely heavily on...