EBMXC Clamped Explosion-Proof Combination Starters

Nema Size starters 00 – 2 may take a 50VA CPT if when there is minimal controls.

- Operating where flammable liquids or gases are handled, processed or used

- Damp, wet, dirty, dusty, hazardous areas where ultimate corrosion and ingress protection is required

- Harsh and hazardous motor control environments, including refineries, chemical and petrochemical plants, corrosive process facilities, food and beverage, marine and mining

- Across-the-line starting, stopping, speed changing and reversing of polyphased AC induction motors

- Clamped enclosure significantly reduces time to enter enclosure and reduces opportunity for missing,

stripped or broken bolts - 65kAIC at 480V enclosure rating for high interrupting capacity applications

- -50°C to +60°C temperature range for extreme environments

- Magnetic, thermal magnetic and electronic break trip options for short circuit and overcurrent protection

- Bi-metallic and electronic/solid state overload protection options

- Normally open (NO) holding circuit contact supplied standard

- Up to six cover operators for a variety of applications

- Side operated breaker handle provides visual confirmation of proper operator alignment while cover is open and can be padlocked in either “ON” or “OFF” positions for OSHA compliance

- Neoprene cover gasket provides NEMA 4X • Maximum wiring room compliance with National Electrical Code requirements allows for easy and safe installation

- Bodies have top and bottom drilled and tapped entries for power and control conduits; removable reducers are supplied standard to accommodate smaller size conduits; all conduit entries are plugged.

- Rugged, corrosion-resistant, cast copper-free aluminum construction provides NEMA 4X protection

- Semi-clamshell enclosure design, with an external flanged ground joint between body and cover, provides increased access to interior components

- Minimum enclosure-to-enclosure spacing with little interference between the opened cover and adjacent enclosure

- Pre-drilled mounting plate for simple starter and breaker installation

- Detachable tap-on mounting feet

- Steel brackets supplied standard for lifting during installation

- NEC/CEC

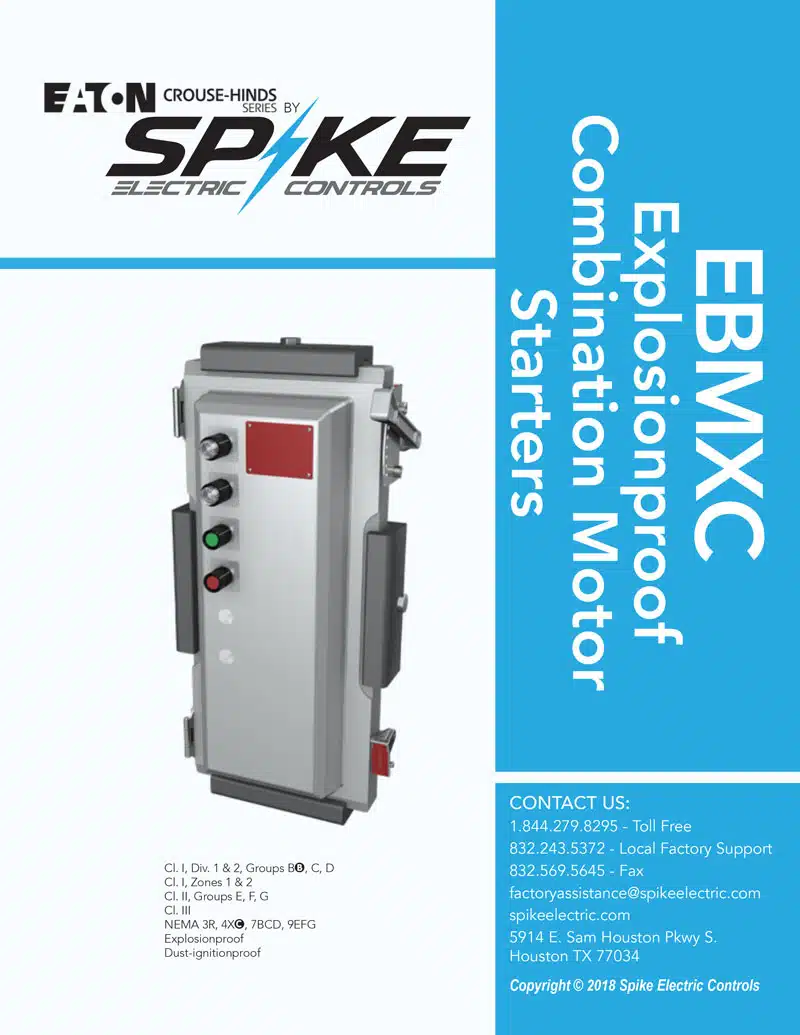

- Class I, Divisions 1 & 2, Groups BB, C, D

- Class I, Zones 1 & 2

- Class II, Groups E, F, G

- Class III

Electrical ratings:

- Motor starters:

– Single-, three-phase

– 3-pole, non-reversing, full voltage

– 600 VAC maximum

– NEMA sizes 0-4• Breakers and HMCPs:

– 3-pole, 600 VAC, 125 VDC

– Eaton frames: EG, JG (up to 250A)D

UL Standards:

- UL1203 – Explosionproof and Dust-ignitionproof Electrical Equipment for use in Hazardous (Classified) Locations

CSA Standard:

– cUL to CSA C22.2 No. 30

Additional Certifications:

– UL/cUL certified for -50°C to +60°C

– SASO Certificate of Conformity

Environmental Ratings:

– NEMA 3R, 4XC, 7BCD, 9EFG

• Body and cover – copper-free aluminum

• Clamp – anodized copper-free aluminum

• External hardware – stainless steel

• Internal parts – galvanized steel

The Only Certified Assembly Partner in the USA & Canada

Spike is strictly audited and certified by Eaton yearly to ensure they follow all quality and safety standards.

By choosing Spike Electric Controls, you're choosing a partner with a unique position in the industry—a partner verified and backed by Eaton Crouse-Hinds.

Our team's specialized training, certification, and local presence ensure you receive:

- Unmatched Service & Support

- Quick & Efficient Logistics: for immediate stock availability.

- Custom Assembly: of ATEX and IECEx-certified products to your exact specifications.

- Assurance of Adherence: to the highest quality standards set by Eaton Crouse-Hinds.

- Annual Audits: confirming our alignment with Hazardous Location Standards.

- Compliance: with the ISO 9001 Quality Management System, meeting Eaton's rigorous standards.

- Expertise: from in-house specialized hazardous location engineers.

- Exclusive In-house Hazardous Location Drilling & Tapping: guaranteeing certified, high-quality processes.