Several industries use medium-voltage equipment for their plant or a project. A lot of industrial workers and personnel commonly ask the question, “Why isn’t an outdoor switchgear system or switchgear enclosure classified as NEMA 3?”

Several industries use medium-voltage equipment for their plant or a project. A lot of industrial workers and personnel commonly ask the question, “Why isn’t an outdoor switchgear system or switchgear enclosure classified as NEMA 3?”

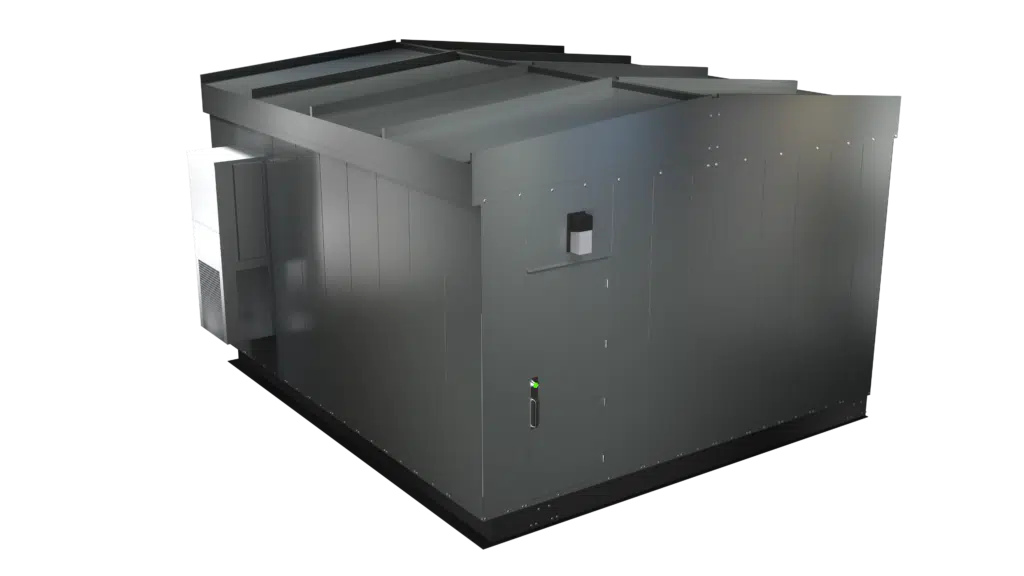

Switchgear is a critical piece of equipment that complies with ANSI/IEEE standards (C37.20.2 or C37.20.3) which, when compared to the NEMA 3 (or “NEMA 3R”) designation, are much more rigorous and demanding. When a switchgear system complies with more complex regulations, a mere NEMA 3 or 3R rating isn’t significant.

What does the NEMA enclosure designation scheme mean? The “Enclosures for Electrical Equipment (1000 Volts Maximum)”, or the NEMA designation scheme, has been defined in NEMA Standard 250. The designation schemes involve NEMA ratings such as NEMA 1, NEMA 3, NEMA 12, etc. The designations and the ratings do not apply to medium-voltage equipment. Hence, medium voltage switchgear building systems do not come under the NEMA 3 or 3R ratings.

Additionally, the NEMA 250 standard is not universal and does not apply to a specific piece of electrical equipment. The designation system is applicable for pieces of equipment that call for the NEMA 250 standard.

For metal-clad switchgear, the relevant standard that must be followed is ANSI/IEEE C37.20.2. For metal-enclosed interrupter switchgear, the standard to be followed is ANSI/IEEE C37.20.3. Among these two standards, neither require nor accept the NEMA 250 designation or ratings for the switchgear building and switchgear enclosure requirements. Hence, the switchgear building design that is developed for use in the outdoors does not require a NEMA 3 or 3R rating to be operated or be used.

What is the purpose of NEMA 3R enclosures? Enclosures that have been designated with a NEMA 3 rating are primarily meant to supply significant protection against rain, sleet, and damage from external ice. When the switchgear system is used outdoors, rain and sleet might be concerning issues. However, ice is not much of an issue as circuit breakers or switch operations, and other operating mechanisms aren’t done outside.

Necessary Tests

A switchgear building or enclosure has been built to withstand the external conditions and complies with more complex and rigorous specifications other than the NEMA ratings. What tests are required to get a NEMA 3R rating for the enclosure? Consider the following:

Rod Entry Test

This test is similar and is equivalent to the one mentioned in ANSI/IEEE C37.20.2 or C37.20.3. standard.

Rain Test

The NEMA 250 rain test is conducted by spraying water from nozzles at a pressure of 5 PSI. The pressure of the sprayed nozzle is approximately equal to the rain-driven wind that traveling at a speed of 5mph. Water is sprayed on all the exposed sides of the enclosure, including the top. However, when compared to the Rain Test prescribed in ANSI/IEEE C37.20.2 or C37.20.3.regulation, the NEMA 3R rain test is inferior. In the C37 test, the water pressure is 60 PSI.

The nozzles that are used to spray water are oriented so that the upper edge of the water spray remains horizontal. This standard ensures maximum safety and high functionality. To stimulate rain-driven speed blowing at a speed of 65mph, higher values are used. Also, in the C37 test, additional nozzles are added. The nozzles are then targeted at the mounting surface like a concrete pad around the equipment.

The purpose of the addition of more nozzles is to check and ensure the water that splashes up from the ground during rain enters the switchgear building or enclosure. This proves that the NEMA 3R rating is much inferior to the C37.20.2 or C37.20.3 rain test.

Since a switchgear building or a switchgear enclosure protects the most critical pieces of equipment in a power distribution system, it must have a more complex and precise rating than a mere NEMA 3 or 3R rating. Therefore, a prefabricated switchgear building that is meant for outdoor use needs standards that are more rigid than the NEMA standards.

Icing Test

Several electrical systems have multiple operating mechanisms within them, which primarily include circuit breakers, switches, and similar pieces of electric equipment. NEMA 3R test is purposed for such operating devices that protrude through the enclosure and are exposed to external weather and environmental conditions. But a switchgear does not have such operating mechanisms on the exterior of the enclosure. Therefore, the icing test for the NEMA 3R rating is highly irrelevant for a switchgear building or enclosure that is used outdoors.

Corrosion Test

NEMA ratings also call for a corrosion test in which salt spray tests are done on the paint system for 200-hours. This process is similar to the corrosion test outlined in the ANSI/IEEE C37.20.2 or C37.20.3. standard. The switchgear building design is developed to ensure that it doesn’t corrode under challenging weather and working conditions. Prefabricated switchgear building is vigorously tested not only for full functionality but also for the quality to see whether it is corrosion-resistant or not.

In a Nutshell

In summary, an outdoor switchgear building or switchgear enclosure that complies with ANSI/IEEE C37.20.2 or C37.20.3 standard is considered to be of the highest quality and superior operational performance. All the requirements required by this standard exceeds the ones of an enclosure rated 3R to NEMA 250.

Are you on the lookout for a quality switchgear building? Does your industrial project require a prefabricated switchgear building? Does your industrial application require a switchgear building design that is customized to suit specific requirements and preferences? Then, Spike Electric is the place for you! With the best industry experts on board, we will craft the perfect switchgear building design for you. We will deliver the perfect prefabricated and pre-assembled switchgear building or enclosure that has been properly tested for full functionality.

Get in touch with our experts today for more information. Our team will assist you in purchasing the perfect enclosure or building for your switchgear systems.

Written by: Cole Attaway

Cole Attaway is the founder and CEO of Spike Electric Controls. Spike's mission is to improve the accessibility and delivery of industrial electrical gear for clients nationwide. Spike solutions result in reduced unplanned downtime, less overtime, and greater operational efficiencies.