Explosion-proof NEMA 7 enclosures are specially designed containers that provide protection against explosions and fires in hazardous environments. They are built to prevent any electrical sparks or arcs from igniting flammable gases, vapors, or dust that may be present in the surrounding atmosphere. In this blog, we will discuss the features of explosion-proof NEMA 7 enclosures and how they work.

Explosion-proof NEMA 7 enclosures are specially designed containers that provide protection against explosions and fires in hazardous environments. They are built to prevent any electrical sparks or arcs from igniting flammable gases, vapors, or dust that may be present in the surrounding atmosphere. In this blog, we will discuss the features of explosion-proof NEMA 7 enclosures and how they work.

Features of Explosion-proof NEMA 7 Enclosures

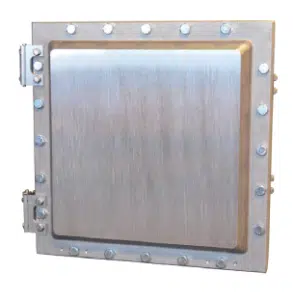

- Material and Construction: Explosion-proof NEMA 7 enclosures are constructed of heavy-duty materials such as cast aluminum, cast iron, or stainless steel. The construction of the enclosure is designed to withstand high levels of pressure and extreme temperatures. The enclosure is also coated with special finishes to protect it against corrosion, ensuring that it lasts long in harsh environments.

- Sealing: The enclosure must be hermetically sealed to prevent the entry of any flammable gases, vapors, or dust. The seal is designed to contain any internal explosion and prevent it from spreading to the surrounding environment.

- Wiring: All wiring and electrical components inside the enclosure may need to be intrinsically safe, meaning they are designed to prevent any electrical sparks or arcs that could ignite any flammable substance in the surrounding environment. Non-intrinsically safe components that arc and spark are allowed in most applications when utilizing Nema 7 hazardous location bolted enclosures. Intrinsically safe or standard electrical components for the internals should be clarified for the end users application.

- Explosion-proof NEMA 7 enclosures must have relief mechanisms that can release any pressure buildup from an internal explosion. The relief mechanisms are designed to direct the explosion in a safe direction, away from personnel and equipment.

- Explosion-proof NEMA 7 enclosures are typically rated for Class 1 Division 1 The equipment or enclosure is suitable for hazardous areas where flammable substances are present at all times.

How Explosion-Proof NEMA 7 Enclosures Work

Explosion-proof NEMA 7 enclosures work by preventing any electrical sparks or arcs from igniting flammable substances in the surrounding environment. If an internal explosion occurs, the hermetically sealed enclosure will contain it, and the explosion relief mechanism will safely direct it in a controlled manner. The intrinsically safe wiring and electrical components inside the enclosure will not create any electrical arcs or sparks that could trigger a secondary explosion.

Explosion-proof NEMA 7 enclosures are commonly used in various industries such as chemical plants, refineries, and oil and gas facilities. They are used to protect electrical equipment such as motors, drives, switches, and control panels from igniting any flammable substance in the surrounding environment. They also ensure the safety of personnel who work in hazardous environments.

In conclusion, explosion-proof NEMA 7 enclosures are essential safety devices that protect against explosions and fires in hazardous environments. Their hermetic sealing, intrinsically safe wiring, and explosion relief mechanisms ensure that internal explosions do not pose any danger to personnel or equipment. If you need an explosion-proof NEMA 7 enclosure for your facility, it is essential to consult with experts to ensure that the enclosure meets the specific needs of your industry and environment.

Written by: Cole Attaway

Cole Attaway is the founder and CEO of Spike Electric Controls. Spike's mission is to improve the accessibility and delivery of industrial electrical gear for clients nationwide. Spike solutions result in reduced unplanned downtime, less overtime, and greater operational efficiencies.