When it comes to safe, reliable, and efficient electrical distribution, low voltage switchgear is at the heart of every industrial and commercial power system. But with evolving safety standards and technological advancements, understanding the requirements for compliant switchgear is more critical than ever. That’s where UL 1558 comes in—the gold standard for low voltage switchgear design and performance.

In this guide, we’ll break down what UL 1558 means, why it matters, and how it ensures the safety and functionality of your electrical systems. Whether you’re an electrical engineer, contractor, or facility manager, this comprehensive guide will give you everything you need to know about UL 1558-compliant low voltage switchgear.

What is Low Voltage Switchgear?

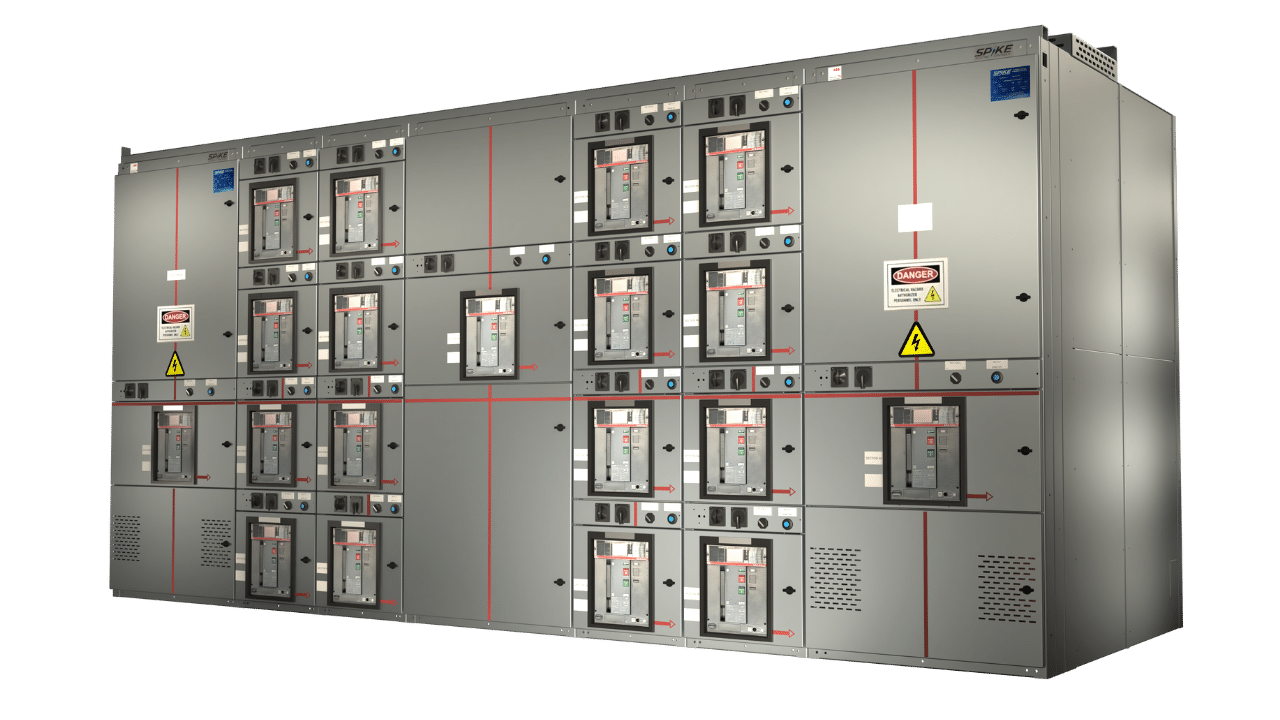

Low voltage switchgear is a centralized system that controls, protects, and isolates electrical equipment in power distribution networks operating at voltages up to 600V. It houses components like circuit breakers, busbars, disconnect switches, and protective relays, all designed to ensure safe power distribution and protect against electrical faults.

Low voltage switchgear is essential in environments like:

- Industrial facilities

- Commercial buildings

- Data centers

- Hospitals

- Utility power distribution

These systems are the backbone of electrical infrastructure, managing how power flows through a facility and ensuring any faults are isolated to prevent system-wide failures.

What is UL 1558?

UL 1558 is the Underwriters Laboratories (UL) safety standard for low voltage metal-enclosed switchgear. It outlines the design, construction, and performance requirements to ensure that switchgear can safely handle electrical loads and fault conditions.

The key focus areas of UL 1558 include:

- Electrical Performance: Defines voltage ratings, short-circuit withstand capacities, and insulation requirements.

- Mechanical Construction: Specifies requirements for the physical structure, including barriers, compartments, and grounding.

- Safety and Testing: Outlines rigorous testing protocols to ensure the switchgear performs reliably under various conditions, including short circuits, temperature extremes, and mechanical stress.

UL 1558-certified switchgear is designed to operate safely in demanding environments, providing peace of mind to engineers and facility operators alike.

Key Features of UL 1558 Low Voltage Switchgear

UL 1558-compliant switchgear brings several benefits that go beyond basic functionality. Here are some of the key features that set UL 1558 equipment apart:

- High Short-Circuit Withstand Ratings: UL 1558 equipment can withstand high fault currents without catastrophic failure. This is critical for environments with large power demands and potential for high short-circuit currents.

- Compartmentalization: The standard requires clear separation between compartments, including bus compartments, circuit breaker compartments, and cable compartments. This enhances safety during maintenance and operation.

- Front and Rear Access: UL 1558 switchgear typically offers both front and rear access for easier installation and maintenance.

- Enhanced Arc Flash Protection: Safety is paramount, and UL 1558 includes provisions for arc-resistant designs to protect personnel in the event of an arc fault.

- Rigorous Testing Protocols: UL 1558 mandates extensive testing, including dielectric testing, temperature rise tests, and short-circuit testing, ensuring the switchgear can handle real-world conditions.

Why UL 1558 Compliance Matters

Compliance with UL 1558 isn’t just about meeting regulatory requirements—it’s about ensuring the safety, reliability, and efficiency of your electrical systems. Here’s why UL 1558 matters:

- Safety: UL 1558 switchgear is designed to minimize the risk of electrical fires, arc flashes, and equipment failure. The standard’s rigorous testing ensures the equipment can withstand electrical faults without endangering personnel or property.

- Reliability: By meeting stringent design and performance criteria, UL 1558 switchgear offers consistent performance over its lifespan, reducing downtime and maintenance costs.

- Regulatory Compliance: Many jurisdictions require UL-listed equipment for new installations and upgrades. Using UL 1558-certified switchgear ensures you meet local and national electrical codes.

- Peace of Mind: Knowing your switchgear is UL 1558 certified means you can trust it to perform under the most demanding conditions.

UL 1558 vs. Other Standards

You might wonder how UL 1558 compares to other standards like UL 891 or IEC 61439. Here’s a quick breakdown:

- UL 1558 vs. UL 891: UL 891 governs switchboards, which are generally smaller and less complex than switchgear. UL 1558 switchgear offers higher short-circuit ratings, better compartmentalization, and enhanced safety features compared to UL 891 switchboards.

- UL 1558 vs. IEC 61439: IEC 61439 is the international standard for low voltage switchgear and controlgear assemblies. While similar, UL 1558 is more stringent in certain areas like short-circuit withstand ratings and testing procedures, making it the preferred choice in North America.

Applications of UL 1558 Low Voltage Switchgear

UL 1558 switchgear is used in a wide range of applications where safety and reliability are critical. Some common applications include:

- Industrial Plants: Managing high-power machinery and ensuring operational continuity.

- Data Centers: Protecting sensitive equipment from power disruptions.

- Hospitals: Ensuring reliable power for critical medical equipment.

- Commercial Buildings: Distributing power efficiently across large facilities.

- Utility Power Distribution: Safeguarding public power infrastructure.

Technical Specifications of UL 1558 Low Voltage Switchgear

To understand the technical depth of UL 1558, it’s essential to explore the detailed specifications and standards it aligns with. The IEEE Std C37.20.1-2015 standard complements UL 1558 by outlining design and performance criteria for metal-enclosed low-voltage power circuit breaker switchgear.

- Short-Circuit Withstand Ratings:

The rated short-circuit withstand current determines the minimum bus bracing required. For low-voltage AC switchgear assemblies, this rating is equal to the short-circuit current rating of the lowest-rated circuit breaker used in the assembly. This ensures that even the weakest link in the system meets stringent safety requirements.

– AC Switchgear: Must withstand short-circuit conditions for at least four cycles on a 60 Hz basis.

– DC Switchgear: Rated to withstand peak currents when tested with a DC source, ensuring robustness against transient faults. - Temperature Limitations:

The limiting temperature for low voltage switchgear is the maximum temperature permitted for primary and secondary circuit components, insulating media, and structural members. Adherence to these temperature constraints prevents overheating, thus extending the equipment’s lifespan and ensuring safe operation. - Bus and Connection Materials:

Buses and primary connections are typically made of copper or aluminum, with ratings designed to meet or exceed the cumulative circuit breaker load. This ensures consistent conductivity and mechanical strength under operational stress. - Dielectric Testing:

UL 1558 mandates dielectric tests to verify the insulation system’s ability to withstand high voltages. This includes power frequency withstand tests and DC voltage withstand tests, ensuring no dielectric breakdown occurs under peak load conditions. - Control Wiring Standards:

The correctness and insulation of control wiring are verified through continuity checks, insulation resistance tests, and polarity verification. These measures prevent faults due to wiring errors and ensure reliable operation of control circuits.

By adhering to these technical specifications, UL 1558 low voltage switchgear provides a robust, safe, and efficient solution for power distribution needs across various industries.

The Technical Blueprint of Low Voltage Switchgear: Navigating UL 1558 Standards

When it comes to designing and implementing safe, efficient, and reliable electrical systems, understanding the technical intricacies of low voltage switchgear is crucial. UL 1558 provides a comprehensive standard for metal-enclosed low-voltage power circuit breaker switchgear, setting the benchmark for performance, safety, and construction.

1. Rated Maximum Voltage and Insulation Levels

The UL standard outlines specific voltage and insulation requirements to ensure that low voltage switchgear can handle various operational demands. The rated maximum voltages for AC systems include 254V, 508V, 635V, 730V, and 1058V, while DC systems span from 300V to 3200V. Each voltage level corresponds to specific insulation requirements, verified through dielectric testing to prevent breakdowns under high-stress conditions.

For instance, AC switchgear rated at 1058V must withstand a power frequency voltage of 3.0 kV RMS and a DC withstand voltage of 4.2 kV. This ensures robust insulation capable of withstanding transient overvoltages and maintaining operational integrity.

2. Continuous Current Ratings and Temperature Limitations

The continuous current rating of switchgear defines the maximum current it can carry without exceeding temperature limits. AC switchgear offers preferred ratings from 1600A to 10,000A, while DC systems extend up to 12,000A. These ratings are critical for ensuring the switchgear operates efficiently without overheating.

Temperature limitations are strictly defined for both insulating materials and busbars. For example, Class 90 insulating materials have a hottest-spot temperature limit of 90°C, while silver-surfaced bus connections can tolerate up to 105°C. These specifications guarantee that components perform reliably under continuous load conditions.

3. Short-Time Withstand and Short-Circuit Ratings

Short-time withstand current is a critical factor in determining the durability of switchgear under fault conditions. UL 1558 specifies that AC switchgear must endure short-time currents for two cycles (0.5 seconds), with a 15-second interval before the next cycle. The short-circuit withstand current defines the maximum fault current the switchgear can handle without mechanical or thermal failure.

For AC systems, the power factor during testing must be 15% lagging or less, ensuring realistic fault simulations. DC switchgear must withstand peak currents that match or exceed their short-time ratings, with tests conducted using high-current DC sources to validate performance.

4. Busbar Construction and Connection Standards

Busbars are the backbone of electrical distribution within switchgear, and their construction is paramount to system efficiency. UL standards require busbars to be made from high-conductivity copper or aluminum, with precise sizing based on current ratings. For example, a 3000A rated busbar should utilize 3 x 0.25” x 5” copper bars per terminal, ensuring minimal resistance and heat generation.

Busbars must also be mechanically braced to withstand short-circuit forces, preventing movement that could lead to electrical faults. Insulation systems, whether air-insulated or fully encapsulated, must meet dielectric requirements to avoid arcing and ensure operational safety.

5. Enclosure Design and Environmental Considerations

The physical construction of metal-enclosed switchgear is as important as its electrical components. UL 1558 mandates that enclosures provide protection against environmental factors like dust, moisture, and mechanical impacts. Enclosures must meet minimum thickness requirements, such as MSG No. 11 for barriers, and be designed to facilitate adequate ventilation without compromising structural integrity.

For outdoor switchgear, enclosures must pass rigorous rain tests to ensure water resistance. Gaskets and seals must withstand temperature extremes and UV exposure, maintaining their integrity over the equipment’s lifespan. The use of corrosion-resistant materials and coatings is essential for long-term durability, especially in harsh industrial or coastal environments.

6. Grounding and Safety Protocols

Proper grounding is critical to the safety and performance of low voltage switchgear. UL standards specify that all metal parts of the switchgear must be connected to a system ground using low-resistance connections. This minimizes the risk of ground faults and protects personnel from electric shock hazards.

For DC systems, grounding protocols vary based on the application. High-resistance grounding may be used in transit systems to limit fault currents, while low-resistance grounding provides a direct path to ground, enhancing safety in industrial applications. Insulation tests are conducted to verify the integrity of grounding systems, ensuring compliance with safety standards.

7. Testing and Certification Requirements

Switchgear must undergo extensive testing to verify compliance with UL standards and ensure operational reliability. Key tests include:

- Dielectric Withstand Tests: Verifying insulation integrity under high-voltage conditions.

- Temperature Rise Tests: Ensuring components can handle continuous loads without overheating.

- Short-Circuit Tests: Validating the switchgear’s ability to withstand fault currents without damage.

- Mechanical Endurance Tests: Assessing the durability of moving parts and interlocks over repeated operations.

Production tests are conducted on each unit to ensure quality control, while field tests verify performance after installation. Compliance with these testing protocols guarantees that the switchgear meets the highest standards for safety, reliability, and performance.

By adhering to the rigorous specifications of UL 1558, low voltage switchgear not only ensures safe and reliable electrical distribution but also sets a benchmark for industry excellence. Understanding these technical requirements is essential for engineers, contractors, and facility managers looking to optimize their power systems.

The Essential Guide to Startup Commissioning and Testing of Low Voltage Switchgear

When it comes to ensuring the longevity, safety, and optimal performance of low voltage switchgear, startup commissioning and testing are non-negotiable steps. Whether you’re deploying new equipment or upgrading an existing system, proper commissioning is the bridge between installation and reliable, long-term operation.

In this guide, we’ll break down the critical steps of the commissioning process and explain why partnering with a certified NETA testing company or the manufacturer’s field service is crucial. These practices not only guarantee compliance with UL 1558 and IEEE standards but also protect your equipment’s warranty and ensure your system operates safely and efficiently according to NEC regulations.

1. What is Startup Commissioning?

Startup commissioning is the process of verifying that low voltage switchgear is installed correctly, functions as intended, and meets all design specifications. This step ensures that the equipment can handle real-world operating conditions without failure, minimizing risks such as electrical faults, equipment damage, or downtime.

Commissioning typically includes:

- Visual and Mechanical Inspections

- Electrical Testing and Calibration

- Functional Performance Testing

- System Integration Verification

Proper commissioning sets the foundation for safe, reliable, and efficient operation throughout the equipment’s lifecycle.

2. The Importance of Professional Testing Services

To ensure your low voltage switchgear operates within safety and performance standards, it’s highly recommended to use a certified NETA (InterNational Electrical Testing Association) testing company or the manufacturer’s field service team that follows UL and IEEE guidelines in the manufacturing process.

Why choose certified professionals?

- Maintains Warranty Coverage: Using unauthorized personnel for testing can void the manufacturer’s warranty. Certified NETA companies or manufacturer services ensure your warranty remains intact.

- Adherence to Industry Standards: Certified testing companies follow strict guidelines, such as ANSI/NETA ATS (Acceptance Testing Specifications) and NEC regulations, ensuring your switchgear meets industry safety and performance benchmarks.

- Expertise in Complex Systems: Low voltage switchgear can be intricate, with multiple components requiring precise calibration and testing. Certified professionals are trained to handle these complexities accurately.

- Safety Compliance: Proper commissioning minimizes risks like arc flash incidents, short circuits, and equipment failure, safeguarding both personnel and assets.

3. Key Steps in Low Voltage Switchgear Commissioning

A. Visual and Mechanical Inspection

The first step involves a thorough inspection of the switchgear to ensure all components are installed correctly and securely. Key checks include:

- Verifying proper alignment and secure mounting of components.

- Inspecting busbars for correct connections and proper insulation.

- Checking for foreign objects, dust, or debris inside enclosures.

- Ensuring that grounding connections are properly installed.

B. Electrical Testing and Calibration

This step validates the electrical integrity of the system, ensuring all components function as expected. Common tests include:

- Insulation Resistance Testing: Verifies that insulation levels meet specified requirements, preventing potential leakage currents.

- Dielectric Withstand Testing: Confirms that the switchgear can withstand high voltage conditions without insulation failure.

- Current Transformer (CT) and Potential Transformer (PT) Testing: Ensures accurate measurement and protection system functionality.

C. Functional Performance Testing

Here, the operational capabilities of the switchgear are put to the test:

- Circuit Breaker Trip Testing: Verifies that breakers operate within their specified time and current thresholds.

- Relay Calibration: Ensures protective relays respond accurately to abnormal conditions.

- Control Circuit Testing: Confirms that control and automation systems function correctly.

D. System Integration Verification

This final phase ensures the switchgear integrates seamlessly with the broader electrical system:

- Verifying communication protocols between switchgear and monitoring systems.

- Testing system response under simulated fault conditions.

- Ensuring coordination between protective devices for optimal fault isolation.

4. Benefits of Thorough Commissioning and Testing

Proper startup commissioning delivers numerous advantages that extend beyond initial installation:

- Enhanced Reliability: Ensures that all components operate correctly from day one, reducing the risk of unexpected failures.

- Optimized Performance: Fine-tuning settings during commissioning helps achieve peak operational efficiency.

- Improved Safety: Identifies potential hazards before the system goes live, reducing risks to personnel and equipment.

- Extended Equipment Lifespan: Proper calibration and testing minimize wear and tear, extending the useful life of the switchgear.

5. The Role of UL, IEEE, and NEC Standards in Commissioning

UL 1558 and IEEE guidelines set the benchmark for the design and performance of low voltage switchgear, while NEC regulations govern the safe installation and operation of electrical systems. Commissioning ensures compliance with these standards, safeguarding both the equipment and the people who rely on it.

Using certified NETA testing companies or manufacturer field services that adhere to UL and IEEE manufacturing standards ensures your equipment is tested according to the most rigorous industry protocols. This not only protects your investment but also guarantees consistent performance throughout the switchgear’s lifecycle.

6. Conclusion

Startup commissioning and testing are critical steps in ensuring the safe, efficient, and reliable operation of low voltage switchgear. By partnering with certified NETA testing companies or the equipment manufacturer’s field service team—who follow UL and IEEE guidelines during manufacturing—you not only protect your warranty but also ensure compliance with NEC and industry safety standards.

Incorporating these best practices into your commissioning process will help maximize system performance, minimize downtime, and ensure long-term operational success.

Explore Our PowerClad Medium Voltage Switchgear Options