Modern breakers are built for new technologies, updated safety standards, and faster response times—but that means they often don’t fit into older switchgear lineups. That’s where compartment adapters—also known as breaker compartments, breaker cradles, breaker mounting frames, or even breaker retrofit kits—come into play. These engineered solutions allow new-style circuit breakers to safely operate within legacy gear without replacing the entire switchgear lineup.

In many facilities—particularly in refineries, industrial plants, or substations—operators want to upgrade to modern breakers with digital relays, arc flash reduction features, or improved interrupt ratings. But the original gear may have been designed decades ago for a now-obsolete breaker footprint. A well-designed compartment adapter bridges this gap by creating a mechanical and electrical interface that aligns perfectly with the legacy structure.

However, not all compartment adapters are created equal—and improperly designed adapters can result in serious mechanical, electrical, and safety problems. This isn’t just a bolt-on box or a universal frame. Each adapter must be customized for the specific gear and breaker type it will connect.

According to IEEE C37.59, all retrofit solutions—including adapter assemblies—must undergo design verification. This is a formal engineering process, not a fit-and-fabricate exercise. The standard emphasizes that even minor modifications in geometry, material, or alignment can affect the safe operation of medium voltage switchgear. Testing must demonstrate that the modified assembly performs at or above the level of the original design in mechanical integrity, dielectric strength, thermal limits, and short-circuit performance.

It’s not enough to simply fabricate something that “fits” in the cabinet. Fitment without verification can be deceptive. Factors like:

-

- Breaker racking depth and travel distance: If the travel path is too short or obstructed, the breaker may not engage fully, risking an open connection during operation.

- Racking torque consistency: Torque variation can indicate misalignment or mechanical drag, increasing wear and creating potential failure points.

- Alignment with primary (line/load) and secondary (control wiring) disconnects: Misalignment can lead to arcing, connection failures, or undetected faults.

- Mechanical and electrical interlocks (including safety shutters and position switches): These must engage at the correct sequence to prevent operators from racking in a live breaker or opening doors during energized states.

Each one of these variables must be engineered, modeled in CAD or simulation software, and physically tested in controlled conditions. A misaligned or poorly constructed breaker cradle can cause:

-

- Incomplete racking and improper breaker insertion

- Excessive wear or damage to bus stabs or arc chute interfaces

- Failure of MOC (mechanism operated cell) or TOC (truck operated cell) auxiliary switches

- Arc flash exposure from poor contact mating or interrupted current flow

At Spike Electric, we specialize in designing and fabricating custom compartment adapters that meet all critical specs. Our adapters are engineered in-house with 3D modeling software, validated against IEEE mechanical and electrical tolerances, and built to withstand the same performance expectations as OEM equipment.

We also account for:

-

- Racking interface geometry and torque

- Compatibility with legacy shutters and interlocks

- Required clearances for proper arc flash mitigation

- Preservation of OEM UL/NRTL certifications where applicable

Our cradle kits often include not just the adapter hardware, but everything needed to safely and seamlessly integrate a modern circuit breaker into a legacy switchgear assembly. Because you’re not just modifying a housing—you’re replacing a core piece of your protection system. This process requires precise engineering and, just as critically, an experienced field service specialist to evaluate the existing gear, perform dimensional verification, and ensure proper installation.

Our kits are designed and supported by our engineering team and implemented by qualified field personnel who understand racking forces, electrical interface conditions, and site-specific clearance constraints. Spike Electric performs on-site assessments to confirm gear compatibility and ensure each retrofit meets the IEEE and UL/NRTL standards.

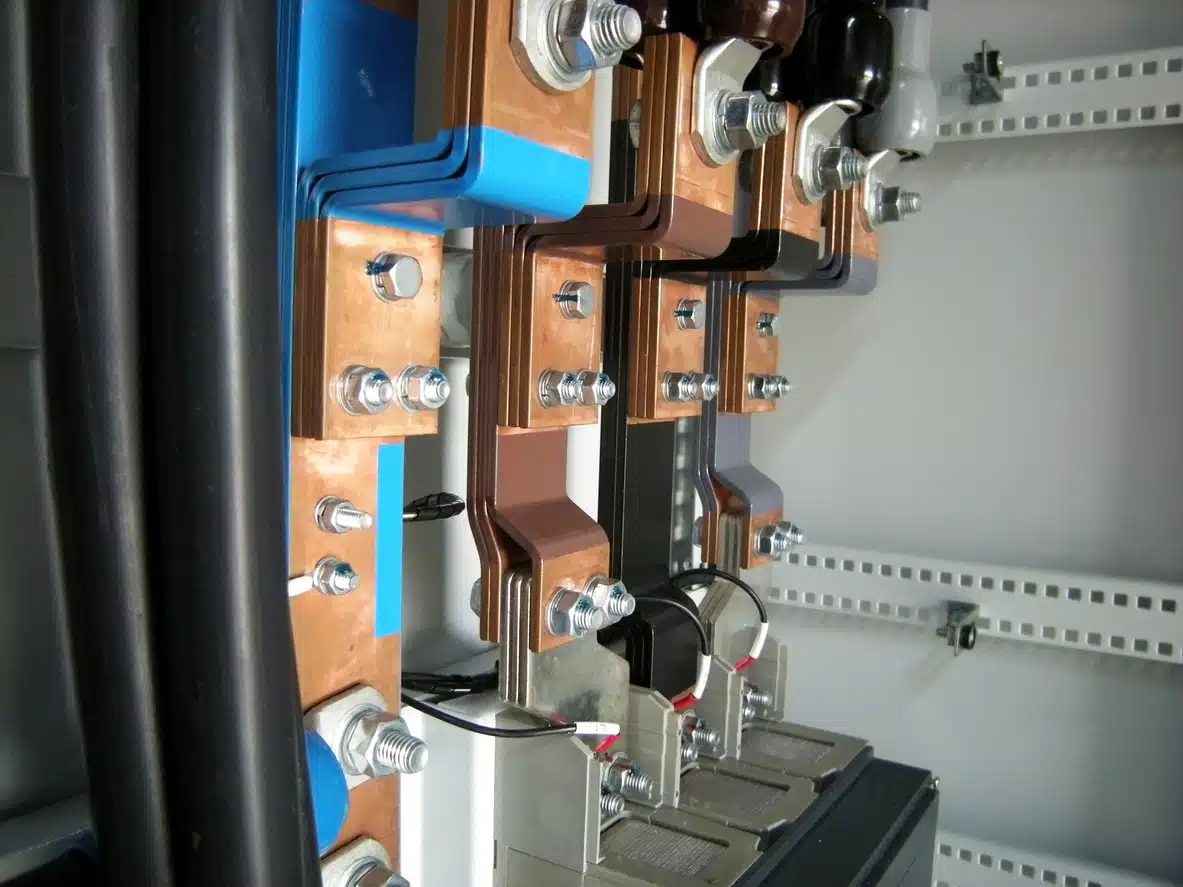

Typical cradle kit components include:

-

- Custom adapter plates

- Mounting brackets

- Breaker racking interfaces

- Mechanical interlock adjustments

- Revised nameplates and documentation

Integrated questions — answered:

Can new breakers fit in old switchgear?

Yes, but not directly. Most modern circuit breakers have different footprints, connection points, and interlock systems. A properly engineered compartment adapter or breaker cradle is required to bridge the mechanical and electrical differences and ensure a safe, code-compliant fit.

What is a switchgear compartment adapter?

A switchgear compartment adapter—also called a breaker cradle or retrofit mounting frame—is a custom-engineered assembly that allows a modern circuit breaker to be installed into older or obsolete switchgear without replacing the entire cabinet. It aligns critical interfaces like racking mechanisms, bus stabs, interlocks, and control wiring.

Are adapter conversions safe?

Adapter conversions are safe only when designed, tested, and installed correctly. Spike Electric follows IEEE C37.59 design verification standards and works with NRTLs (like UL and Intertek) to ensure all modifications meet electrical, mechanical, and safety requirements.

Do I need new racking mechanisms with a retrofit?

Often, yes. The new breaker may require a different racking interface or travel path. Our cradle kits include custom racking interfaces designed to match the torque, depth, and travel requirements of the new breaker.

Can I still use MOC switches with a new breaker?

Yes, in most cases. We engineer each cradle to preserve or replace MOC (mechanism operated cell) switches as needed. Compatibility with TOC (truck operated cell) auxiliary switches is also reviewed during design.

What’s the difference between a cradle and a compartment adapter?

The terms are often used interchangeably, but generally:

-

- A breaker cradle refers to the mounting structure that holds and guides the breaker into position.

- A compartment adapter refers to the broader assembly that may include cradle, racking parts, bus alignment guides, and enclosure hardware. Spike Electric typically provides a full kit combining both.

How do I verify that my adapter conversion is code compliant?

Code compliance requires more than a visual fit. Your adapter must meet IEEE C37.59 design criteria, maintain UL/NRTL certifications (when applicable), and be documented for NFPA 70E and OSHA 1910 compliance. Spike Electric provides full drawings, test records, and nameplate updates for verification.

Will I still meet IEEE and UL standards with an adapter kit?

Yes—if the kit is designed, fabricated, and installed by a certified manufacturer like Spike Electric. We ensure that all components and integration methods align with IEEE standards and are compatible with existing or updated UL labeling when coordinated with the original equipment listings.