But can the same method be executed for larger applications like heavy industrial units and manufacturing units? No. The diameter must be increased as the amount of current being transported through the wiring increases. At some point, this is practically impossible, as high units of power or current cannot be transmitted through gigantic, insulated wiring systems.

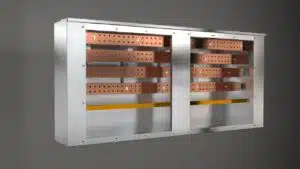

What can be done during such an event? Bus bars are used for power distribution. Bus bars are usually made of aluminium, copper, and brass. The operational method and the design of bus bars are different from that of insulated wiring. How? Insulated wiring runs inside the conduit, while the bus bar requires a specific and special type of enclosure called a Bussed Gutter.

What is a Bussed Gutter?

A bussed gutter can be considered an efficient distribution point for multiple load applications. It is a very economical solution for high current transmission and can handle current up to 2000 amps. A bussed gutter is a flexible power distribution solution and is a highly effective piece of equipment for applications that require change and adaptation.

The primary goal of the bussed gutter is to split primary power circuits into secondary circuits and to supply fixed junction tap-off points.

The Bussed Gutter Design

A bussed gutter design has a lot of specifications that make it an ideal choice to distribute power under multiple load conditions. A bussed gutter has an aluminium bussing, and the distribution point is found under a common feed with the same surface mount.

Eaton Bussed gutters are available in majorly two types- universal bussed gutters that are used for general power distribution and TB/MTB bussed gutters that are meant to group the TB/MTB units to the enclosure with the help of KO’s.

The Eaton Bussed Gutter enclosure is made up of NEMA type 3R enclosure and has a finished aluminium bussing. The bussed gutter design is a labour-saving alternative to conduit systems and multi-tap cabinets. Bussed gutters are available at a length of up to 10 feet and can handle a current flow ranging from 200 amps to 2000 amps.

Bussed Gutter Manufacturing

The manufacturing of the bussed gutter is done keeping two essential things in mind:

The bussed gutter should be completely efficient in protecting the internal connections and bus bars from external environmental factors like dust and challenging weather conditions.

The bussed gutter enclosure should provide 100% electrical isolation from the surroundings. This will ensure the safety and protection of the industry or facility personnel.

Applications Of The Bussed Gutter

Following are some of the applications for which bussed gutters are extensively used:

- Electrical switchyards

- Large commercial facilities

- Industrial manufacturing plants

Advantages Of Using A Bussed Gutter

There are several benefits of using a bussed gutter for multiple loads or high current applications. Following are the most important of them:

A bussed gutter can efficiently dissipate heat

A bussed gutter can efficiently dissipate more heat than an insulated wire that has the same current-carrying capacity. How is this possible? The large surface of the bussed gutter helps it to do so. What is the advantage of this efficient dissipation of heat? It reduces the temperature of the electrical distribution system. Therefore, the service life of the various electrical components increases, making them more durable, and the overall energy efficiency of the installation is also enhanced.

A bussed gutter has bolted and clamped connections

When multiple loads are connected to the same conductor, maintaining electrical connections between wire segments become exceedingly difficult. Why? Because it leads to an increase in the conductor diameter. It is a very impractical solution. On the contrary, a bussed gutter provides the convenience of bolted or clamped connections. These connections can help in powering multiple devices. The same set of bus bars is required.

What To Consider Before Buying A Bussed Gutter?

A bussed gutter hosts current ranging from several hundred amperes to a few thousand. Safety and protection are vital factors to keep in mind before purchasing a bussed gutter. You must choose the right type of enclosure; it is necessary to have the right type of enclosure for the application. The bussed gutter that you are buying will have been tested for full operational efficiency and for complete safety.

In the United States, the National Electrical Manufacturers Association (NEMA) has outlined several regulations and standards for electrical products. The Association is the primary authority for the manufacturing and regulation of electrical products.

NEMA has outlined a classification system for electrical enclosures. This classification system is based on the environmental conditions in which the electrical enclosure is meant to function. The enclosure will be exposed to several kinds of weather and environmental conditions. Only the optimal type of enclosures should be used for applications that consist of hazardous and demanding environments. This will ensure safe operating conditions and will also protect the industry personnel.

Before purchasing a Bussed Gutter, here are some of the factors that you must carefully consider:

- Location: Whether it is meant for indoor or outdoor purposes

- The degree of exposure to dust that the enclosure will have

- The degree of exposure to water that the enclosure will have

- Any signs of the presence of corrosive agents or explosive or flammable materials in the industrial environment

Spike Electric- The Ultimate Destination for Bussed Gutters

With years of experience in the industrial and electrical sectors, Spike Electric deals with premium quality Bussed Gutters for multiple loads and high current applications. If you are on the lookout for Bussed Gutters that efficiently deliver the desired outcomes and ensure the safety of the industry personnel, then get in touch with us soon. We will be happy to help you.

Written by: Cole Attaway

Cole Attaway is the founder and CEO of Spike Electric Controls. Spike's mission is to improve the accessibility and delivery of industrial electrical gear for clients nationwide. Spike solutions result in reduced unplanned downtime, less overtime, and greater operational efficiencies.