Spike Electric’s Most Recent Posts

Do I Need a Breaker Compartment Adapter? Here’s What You Need to Know

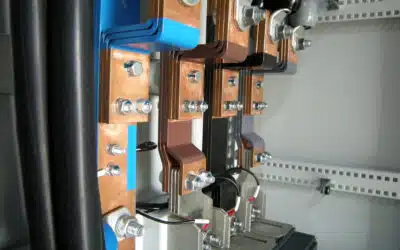

Modern breakers are built for new technologies, updated safety standards, and faster response times—but that means they often don’t fit into older switchgear lineups. That’s where compartment adapters—also known as breaker compartments, breaker cradles, breaker...

What Is a Switchgear Retrofit—and When Does Your Facility Need One?

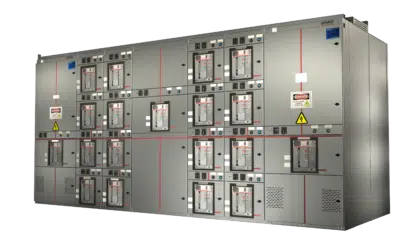

Retrofitting switchgear is a cost-effective way to modernize outdated systems without ripping out and replacing entire electrical lineups. But how do you know when a retrofit is the right move—and what’s at stake if you get it wrong? Switchgear retrofits reuse key...

Understanding IEEE C37.59-2018: An Introduction to Power Switchgear Conversion

When it comes to electrical infrastructure, reliability, safety, and compliance are paramount. Organizations across industries rely heavily on switchgear systems to distribute and control electrical power safely and efficiently. However, as infrastructure ages,...

Safety First: Essential Design Verification in Switchgear Conversions

Understanding Why IEEE C37.59-2018 Treats Design Testing as Non-Negotiable When it comes to electrical infrastructure upgrades, cutting corners is never worth the risk. This is especially true for switchgear conversions, where even minor miscalculations can lead to...

Types of Power Switchgear Conversions and Their Applications Understanding What Can Be Upgraded — and Why It Matters

Modern electrical systems are expected to deliver safety, reliability, and performance even under evolving loads and aging infrastructure. Yet for many facilities, the backbone of their power distribution — the switchgear — is decades old. Replacing it outright is...

Avoiding Common Pitfalls in Switchgear Conversion Projects

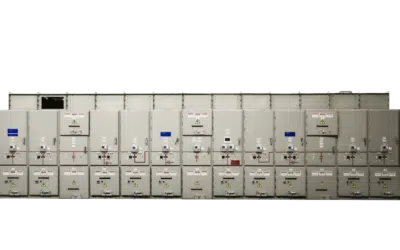

Lessons Learned from the Field and How to Do It Right the First Time In the realm of power distribution, switchgear conversions are a strategic approach to modernize aging infrastructure without the extensive costs and disruptions associated with complete...

Testing Requirements Explained: Ensuring Your Switchgear Conversion Meets Standards

How to Validate Performance, Compliance, and Safety the Right Way In the high-stakes world of electrical infrastructure, upgrading switchgear through conversion is only half the battle. The real test comes when it's time to energize. And the only way to ensure your...

Why Documentation Matters: IEEE C37.59-2018 Compliance

How Proper Records Protect Safety, Support Maintenance, and Prove Compliance When performing a switchgear conversion, it's easy to focus on the physical work—retrofitting breakers, installing relays, or integrating arc flash mitigation. But there is a less visible,...

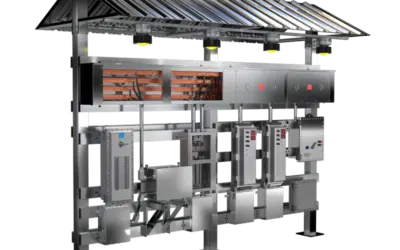

Why Switchracks Still Matter in the HazLoc Market: A Forgotten Standard

In the hazardous location (HazLoc) market, we've seen a troubling shift away from the foundational engineering standards that once defined our industry. Ten to fifteen years ago, industry leader Crouse-Hinds actively educated engineers, EPCs, and end-users about...

Why Spike Electric Controls is the Fastest and Most Innovative Switchgear Manufacturer in the USA

When people search online for the "fastest switchgear manufacturer in the USA," they’re often directed to legacy brands that haven't changed their pace or practices in decades. But the real game-changer in this space isn't a household name—yet. It’s Spike Electric...